UDK WebOffice

UDK’s 75,000-square-meter (800,000-square-foot) factory in Dnipro, Ukraine, produces 440,000 cubic meters (over 15 million cubic feet) of construction materials yearly, covering around 10% of Ukraine’s total autoclaved aerated concrete (AAC) market. UDK works directly with construction companies, developers, and distributors — most orders are wholesale.

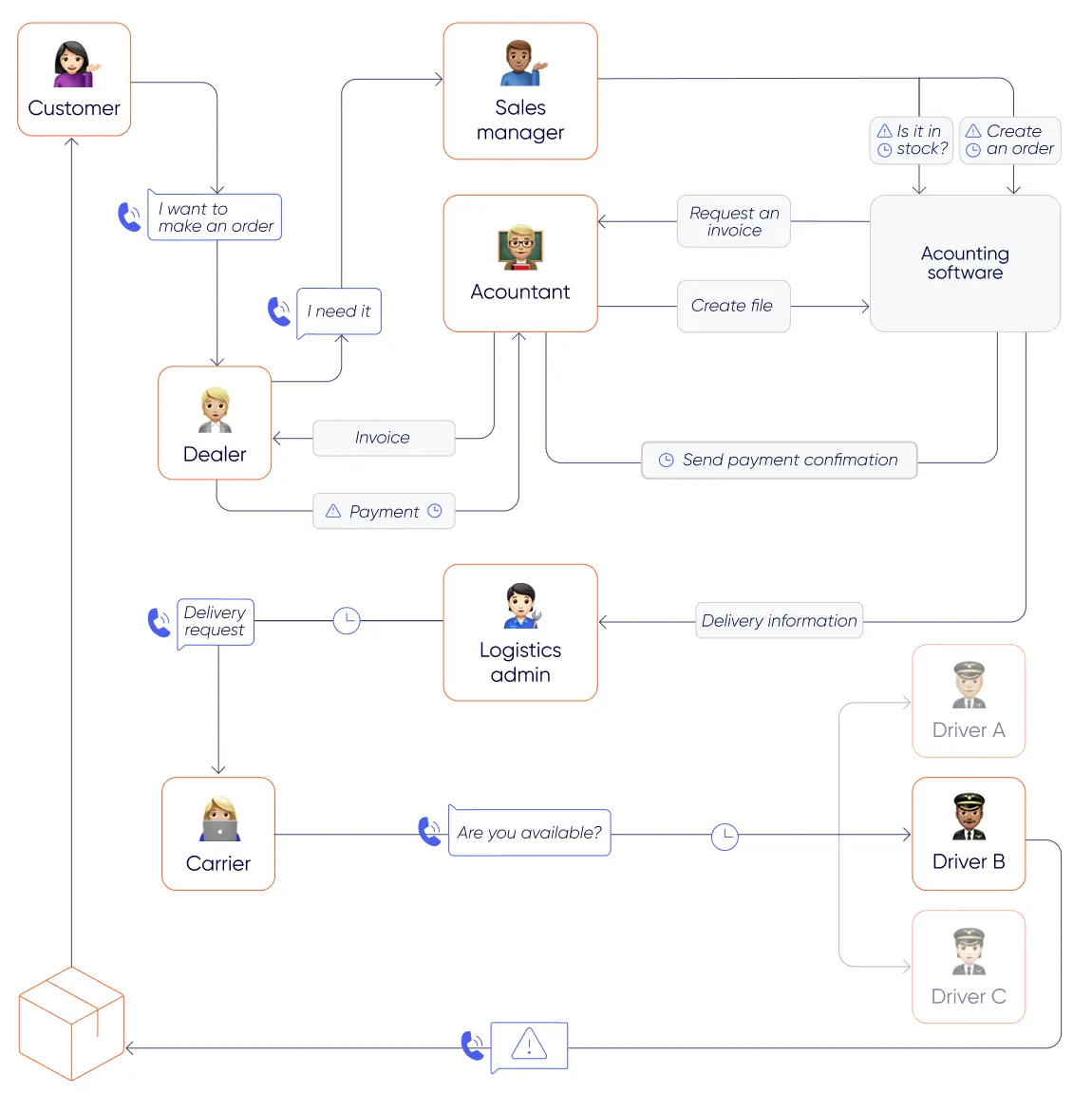

Despite the scale of the company’s operations, however, almost everything was done manually at the moment our partnership began. This resulted in endless calls, handwritten reports, and error-prone delivery planning. Scaling in this way wasn’t sustainable; there was a definite need for digital transformation.

After a brief analysis, it was clear that a full enterprise resource planning (ERP) system would take a few years and millions of dollars to build. But we were after quick, tangible results. So we went with an MVP approach and focused on the core modules that mattered most.

“We kicked things off by mapping out UDK’s existing workflows to understand how everything operated day to day. It didn’t take long to spot the first major blocker — order management. Processing a single order often meant at least five separate phone calls between clients, managers, warehouse operators, and delivery partners. On top of that, the process was full of manual actions and prone to errors. So the next step was clear: we had to tackle order processing first if we wanted to make an impact fast.”

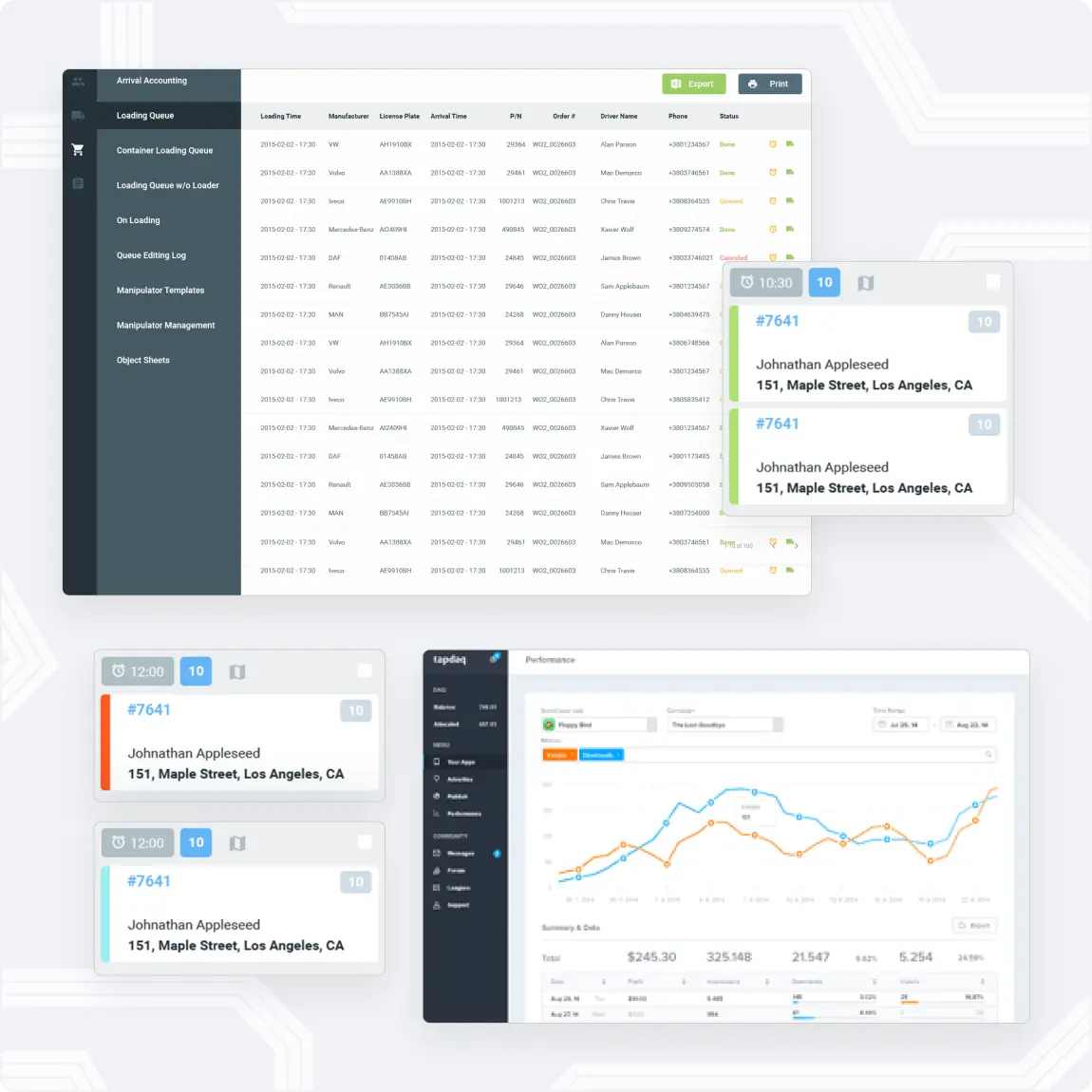

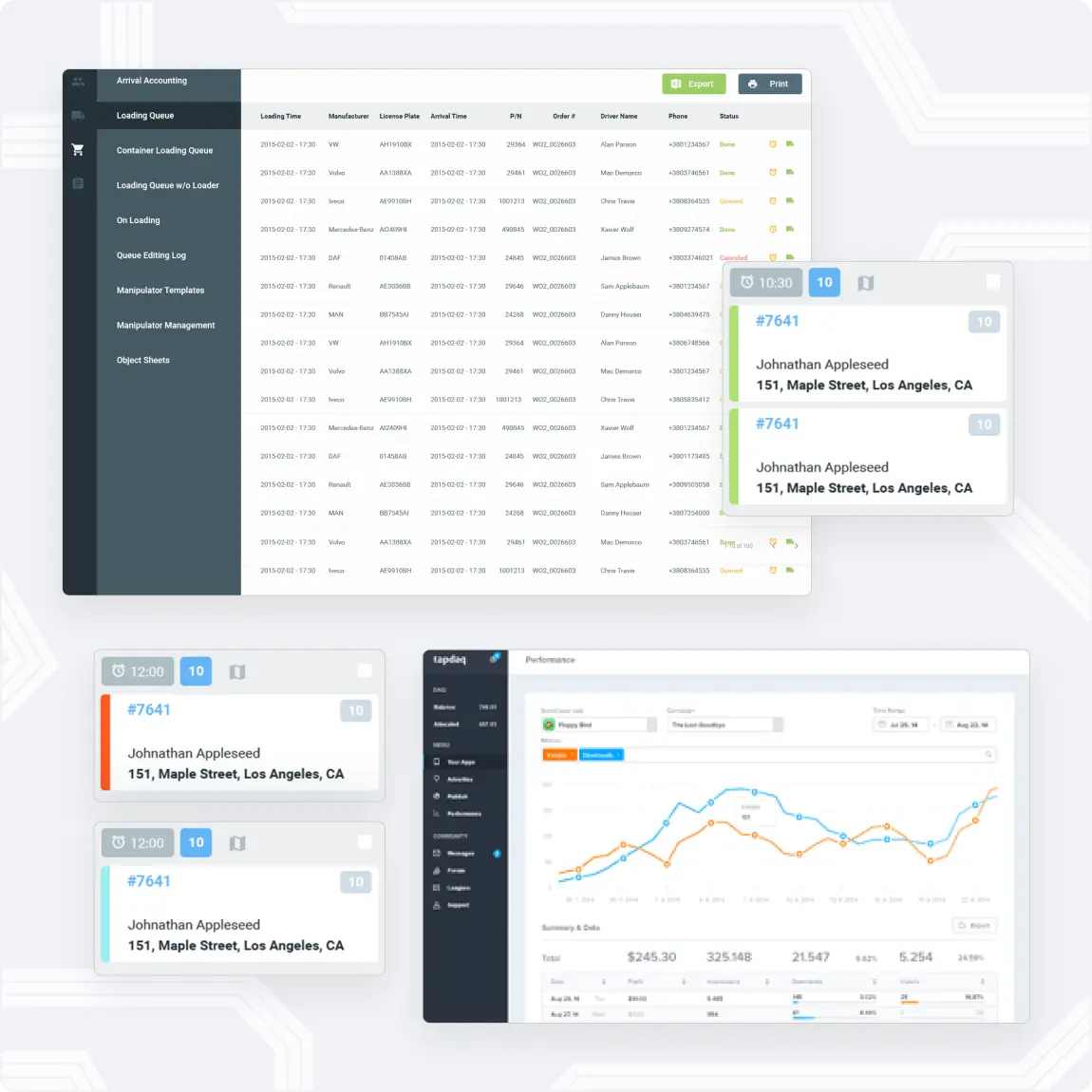

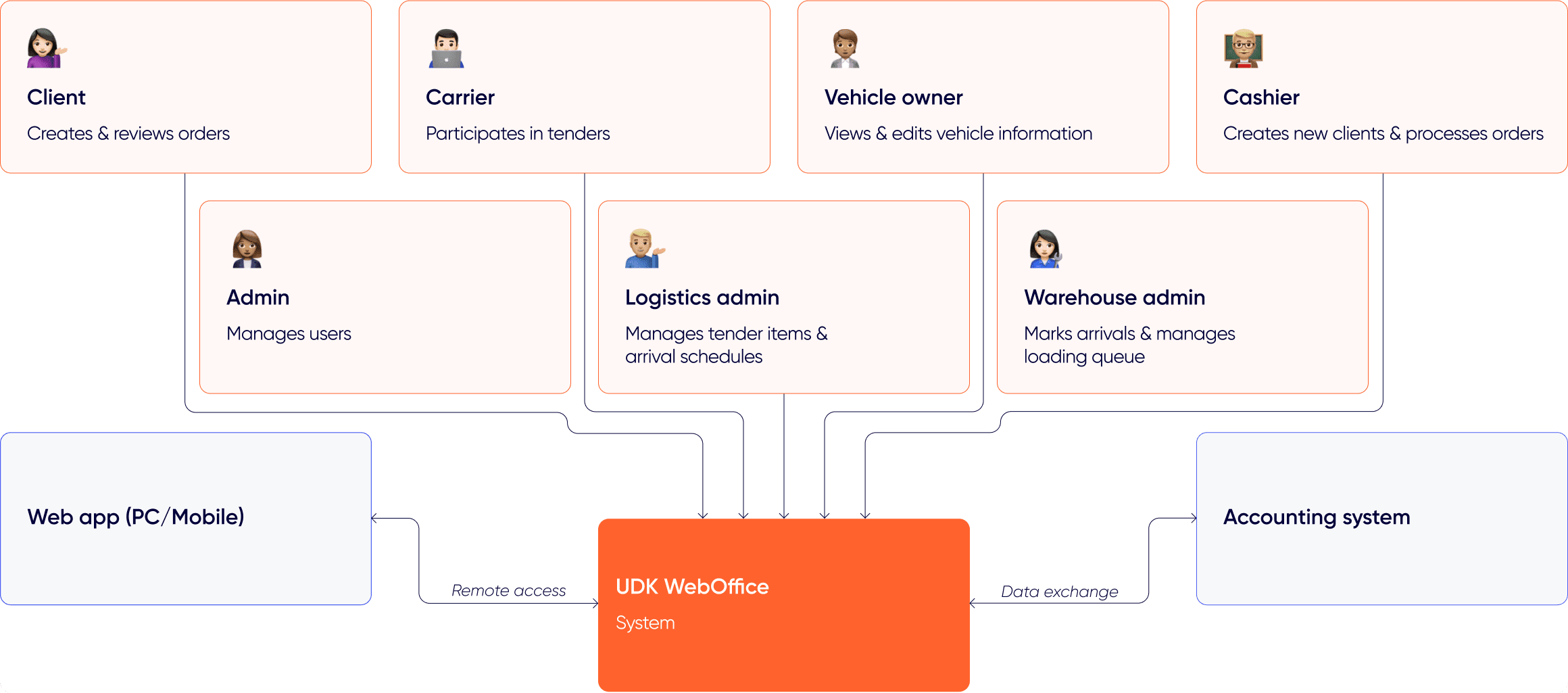

Both internal and external users got access to the WebOffice system with the right permissions and tools for their job. We aimed to improve the experience for everyone involved through:

Once the biggest pain point was out of the way, we took a closer look under the hood of the company. More bottlenecks came up during analysis, and our team methodically worked through them to make UDK’s system smoother at every level.

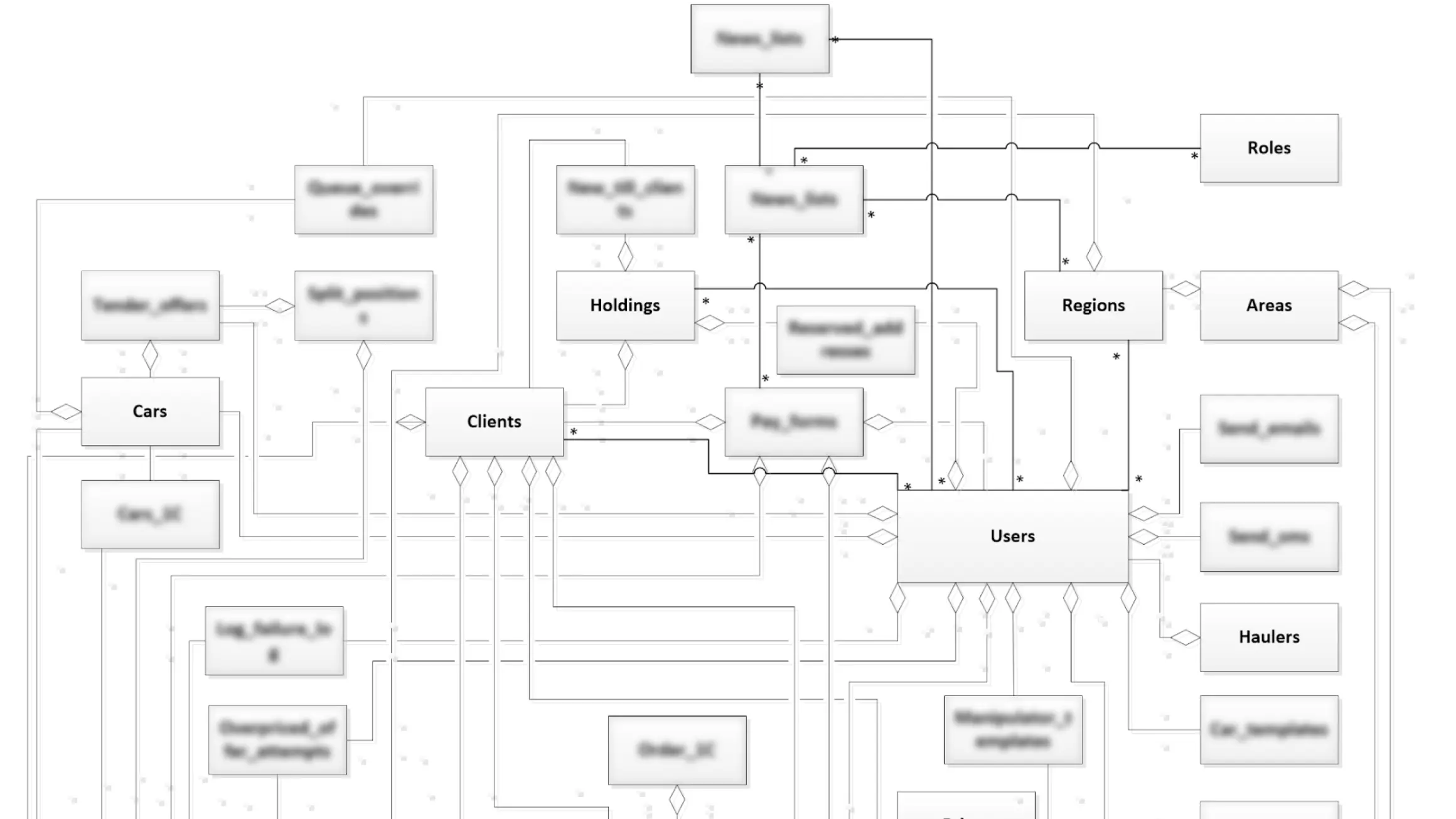

“UDK already had tools in place for accounting, order management, and other operations — and a lot of valuable data spread across different systems. We weren’t there to tear everything down. The goal was modernization, not disruption. We looked for a way to keep the tools their team was used to while connecting everything through a single interface. That also meant unifying the data and defining how all system components and data entities interact, ensuring consistency and making sure the design supported scalability, performance, and future growth.

The system data structure diagram we presented was our solution for connecting all components of the system and ensuring a seamless and error-free data flow.”

This project came with some unique optimization puzzles.

One of them was delivery logistics: We had to assign trucks based on delivery points and vehicle types, build individual route plans, and even arrange cargo inside each truck according to the unloading sequence, since the crane manipulator can only unload in order. And, of course, all of that had to align with the warehouse’s loading schedule.

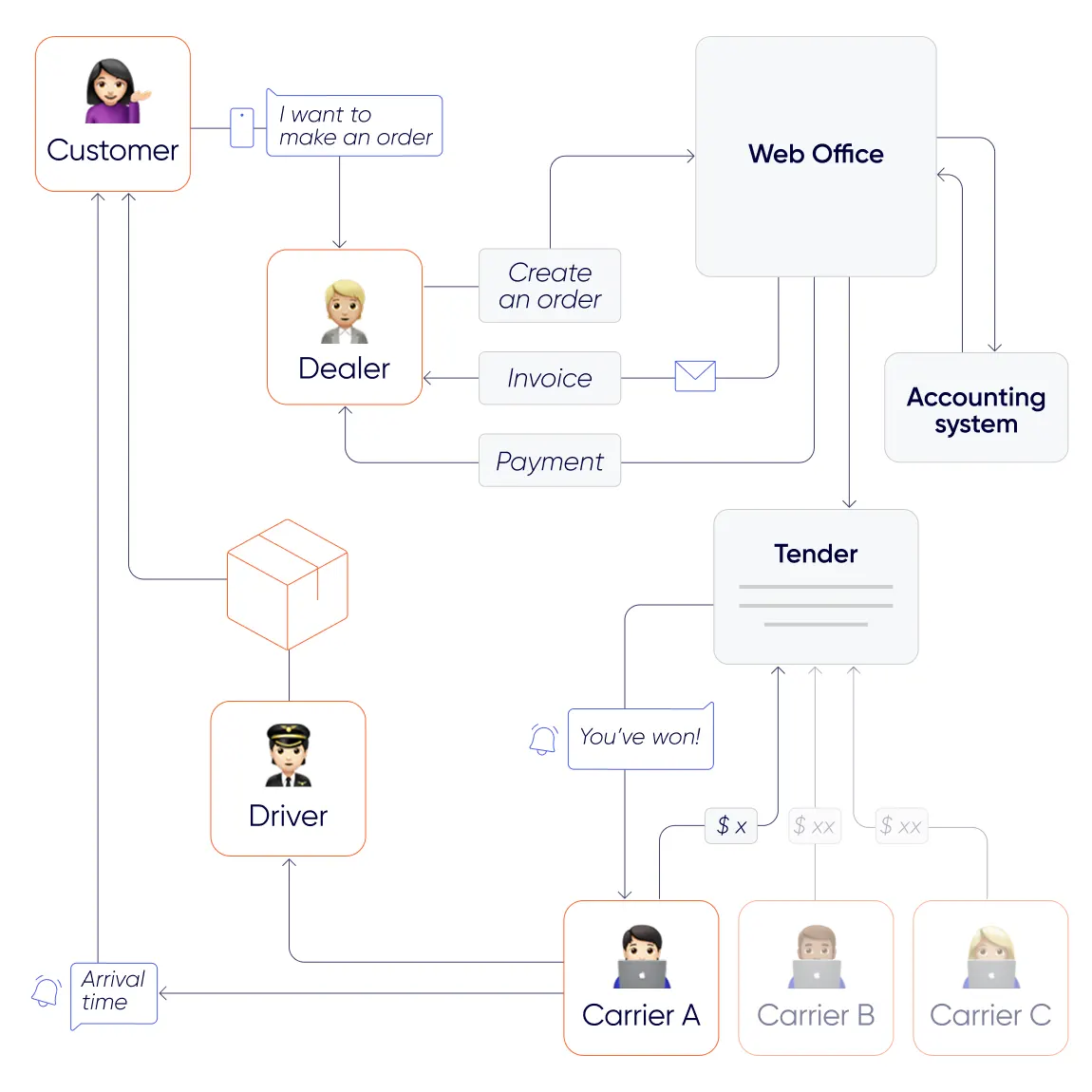

Another issue was carrier assignment. Carriers were often assigned subjectively, leading to delays and higher-than-necessary costs. We solved this with a fully automated auction system: partners bid on upcoming shipments, and the system automatically selects the best offer. This ensures the most profitable assignment for each shipment.

WebOffice brings order management under control, uniting everyone involved in a single, easy-to-use interface.

“UDK wanted to avoid vendor lock-in — and we fully supported that. Their team stayed actively involved in technical discussions to keep context and ownership on their side. To make future support and scaling easier, we also delivered thorough documentation.

One example is the Software Design Description (SDD) — a technical document that outlines the architecture and system design of UDK WebOffice. It’s written for developers who will maintain or extend the system, QA engineers, and third-party teams integrating with WebOffice. In short, it contains everything they need to stay in control of the product.”