AI solutions

What we do

Services

Experts in

How we work

When you’re building a manufacturing ERP from scratch, the possibilities are endless; you can pack it with any feature imaginable. But that’s exactly how systems end up bloated, inefficient, or a nightmare to scale.

The trick is figuring out what features will actually solve your problems and how to build an ERP so it can scale as you grow instead of becoming the next big headache. Luckily, we know how to do it.

We’ve been providing ERP development services since 2014. So, we decided it was time to annoy our business analysts and solution architects to break down the realities of creating ERPs for manufacturers: what makes this type of ERPs different, which features drive efficiency, and what to expect from development (yes, costs included).

Before we get into the details of development, let’s talk about what actually makes a manufacturing ERP... well, for manufacturing. Many businesses start with a general-purpose ERP, only to realize it just doesn’t cut it when you need to manage production lines, track equipment, or keep up with real-time operations. Sure, it handles the basics — inventory, accounting, the usual stuff — but manufacturing has way more moving parts.

A manufacturing ERP is built to manage the chaos of production. What exactly makes it different? Let’s break it down.

A general ERP will help you track sales and invoices, but can it handle bill of material management, production planning, or quality control? Manufacturing ERPs, in turn, support the industry-specific set of workflows. Whether it’s managing multi-stage production, tracking waste, or automating shop floor scheduling, ERP solutions for manufacturing include dedicated modules for these tasks.

Knowing what happened yesterday isn’t enough. Manufacturing requires real-time visibility into production lines, raw material levels, and work orders. Whether it’s live inventory tracking, machine performance monitoring, or instant quality control alerts, manufacturing ERP software keeps your operations in sync.

Generic ERPs usually aren’t built to talk to your factory floor, but an industry-specific system will cover this need. Integrating with IoT sensors, SCADA systems, and CNC machines allows your ERP to collect real-time performance data, automate maintenance alerts, and even optimize production schedules based on machine efficiency.

All in all, with a manufacturing ERP, the focus isn’t just on managing business processes, it’s on making production more efficient, predictable, and scalable, while connecting to ERP in supply chain for end-to-end visibility.

However, building an efficient manufacturing ERP takes a bit more than adding extra features. You need the right development approach. That’s what we’ll talk about next, along with costs, timelines, and high-impact functionality based on what has worked for our clients.

The process of building manufacturing ERP software is the same as that of building any other ERP. We divide it into 3 key stages:

This is the big picture of the development process; each stage has its own little details that make the difference between a manufacturing ERP system that works and one that’s a pain to deal with. Let’s first explore the discovery stage.

This stage is about planning but also about making sure you don’t run into expensive surprises later. Overlooking key details now could cost you an extra $30,000+ in fixes and rework down the road (we’ve seen it when clients skipped proper discovery). That’s why we dive deep into planning upfront, so you don’t hit roadblocks (or budget shocks) midway through development.

During the project discovery stage, our business analyst, project manager, UI/UX designer, and software architect focus on several key areas:

At the start, we’ll meet with you to break down your manufacturing workflows, challenges, and goals. The key here is understanding how your production runs, where inefficiencies slow things down, and what gaps your current systems leave open.

We’ll cover essential questions like:

Your input shapes the next step: defining exactly how your ERP will streamline manufacturing operations.

Once we have a clear picture of your manufacturing processes, we translate that knowledge into a structured plan for your manufacturing ERP software. This is where we define what your software needs to do to support production, inventory, quality control, and every other critical operation.

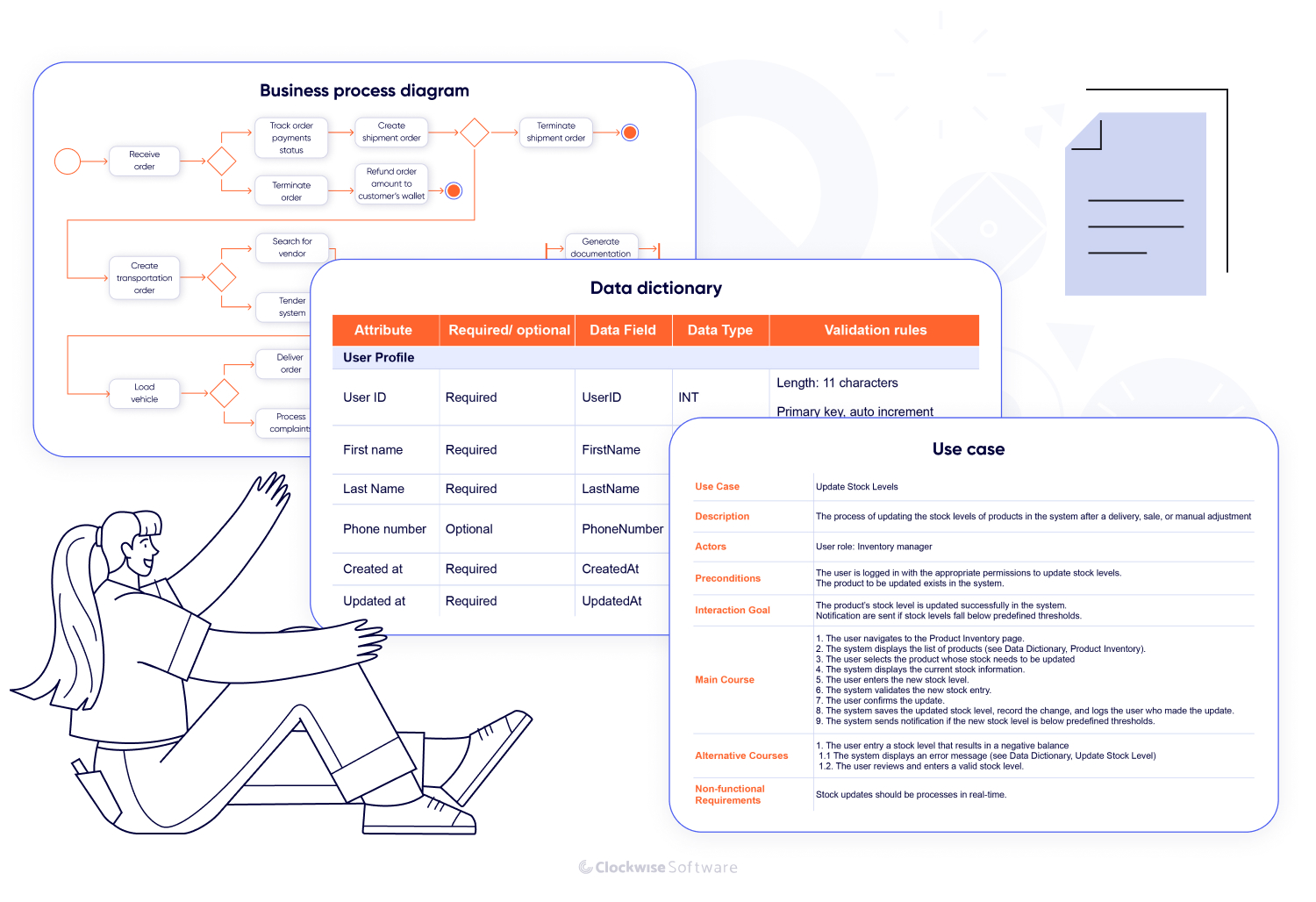

You’ll get a detailed breakdown of your ERP’s functionality, documented in clear, structured formats, including:

This step ensures that everyone — your team and ours — is aligned on what your manufacturing ERP will deliver before we write a single line of code.

Before development starts, we explore potential technical risks, ensuring integrations, security, and data migration won’t cause issues later.

One of the most critical areas we examine is integration with external tools. Whether it’s MES, PLCs, or third-party APIs, each comes with quirks and limitations. Our software architect reviews documentation, tests connections, and ensures everything works as expected.

For high-risk cases, we build a proof of concept to simulate real-world interactions, validate APIs, and compare service options. This upfront work will help us avoid roadblocks, streamline implementation, and keep your ERP project on track.

Now, we turn the wireframes we did earlier into full UI/UX designs that match your vision and workflows. Our designer refines the interface based on your feedback, ensuring clarity, usability, and efficiency.

We also create an interactive prototype so you can click through screens, see how users navigate, and fine-tune details before development begins. We’ll walk you through everything to ensure it’s exactly what your team needs.

Next, we define how your manufacturing ERP will be built, scaled, and maintained. This includes choosing the right technologies and structuring the system for security, flexibility, and long-term performance.

JavaScript is our primary choice for web development — it’s versatile, widely supported, and ideal for building complex applications.

On the front end, we typically use React, Angular, or Vue.js to build intuitive and responsive interfaces.

On the back end, we work with Express.js or Nest.js to handle business logic, APIs, and integrations. If your project requires PHP, we also have solid experience with Laravel for building scalable ERP backends.

Choosing the right system architecture is critical for scalability and maintainability. We find that a service-oriented approach (SOA) works best for ERP systems. It provides flexibility without the complexity of full microservices.

Instead of one large monolithic application, we divide the system into modular services: for example, an authentication API, a customer API, and integrations with external tools like accounting software.

We also design services using a layered architecture, ensuring they are well-structured, scalable, and easy to enhance over time. If ERP software for a manufacturing company requires real-time processing (e.g., IoT data from manufacturing machines), we consider event-driven patterns for handling live data efficiently.

When it comes to infrastructure for cloud-based ERP software, we rely on AWS, Azure, or Google Cloud to ensure your ERP is highly available, scalable, and secure. For example, we often use Elastic Beanstalk for automatic scaling and AWS Lambda for serverless functions that reduce infrastructure overhead. To simplify environment management, we implement Infrastructure as Code (IaC) with Terraform or AWS CloudFormation, which allows us to version-control and replicate environments seamlessly.

We apply data encryption, role-based access control (RBAC), and automated backups with services like AWS Backup or Google Cloud Storage to ensure business continuity. If you have specific compliance requirements, we’ll adapt security measures accordingly.

To keep the system running smoothly, we integrate tools like AWS CloudWatch or Azure Monitor for real-time tracking, along with third-party solutions like New Relic and Sentry for deep performance insights and issue tracking.

We choose the database structure based on your ERP’s needs. If structured business data is the priority, we go with PostgreSQL or MySQL. If handling unstructured or IoT-generated data is crucial, MongoDB provides the needed flexibility.

Every decision we make on this step ensures your manufacturing ERP is designed to last, scale, and align with your business goals.

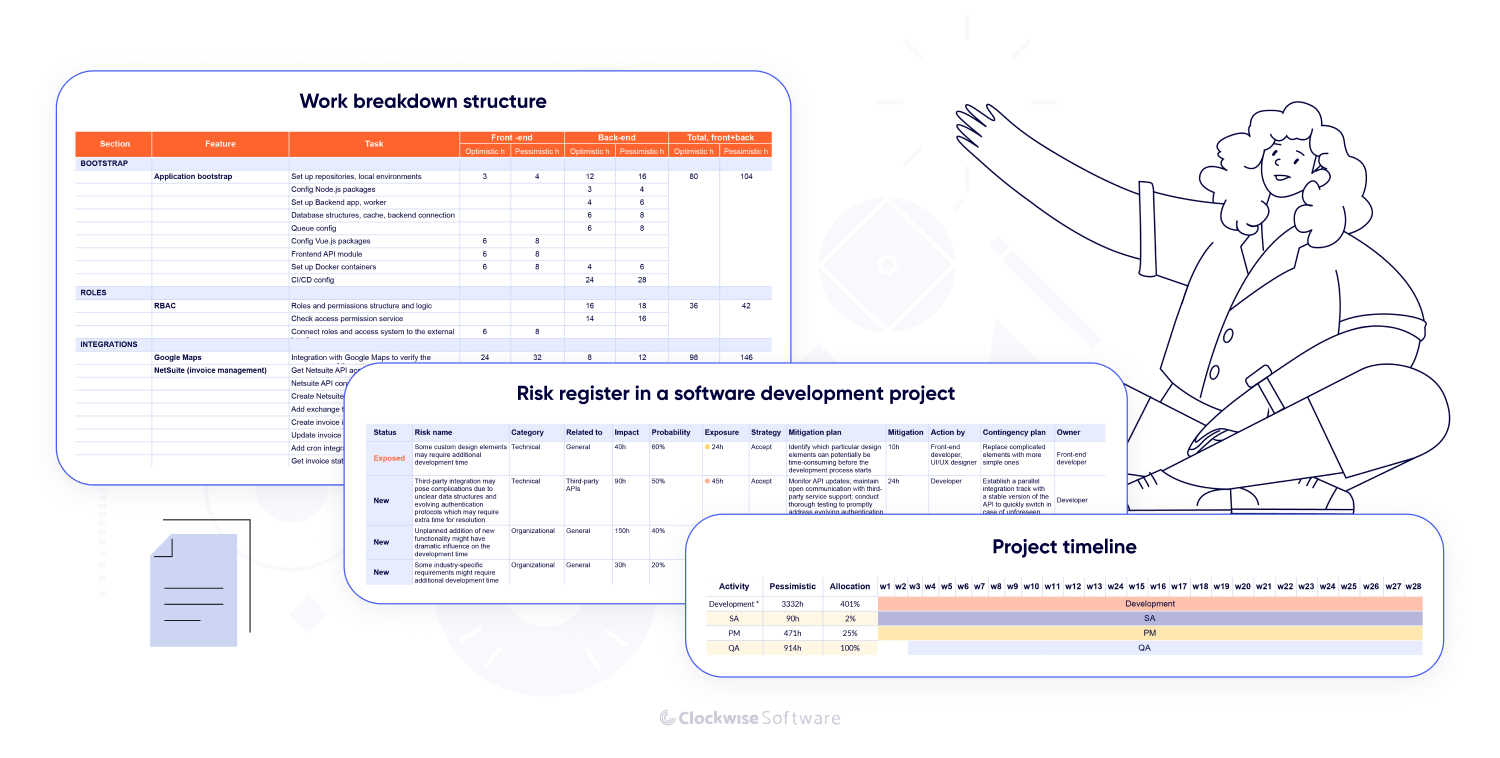

We’re wrapping up the discovery stage by finalizing documentation and structuring the development plan. At this stage, you’ll get:

By the end of the discovery stage, you’ll have a clear blueprint of your ERP for manufacturing, complete with estimates and a structured plan to bring it to life.

But here’s something to keep in mind from the start:

ERP development isn’t a fixed-budget process

These systems are complex, and projects often span 9+ months or even years. Along the way, new insights, shifting priorities, or unforeseen challenges can impact the scope, timeline, and budget.

That’s why we provide both realistic and pessimistic estimates, keeping you in the loop at every stage. We plan for adjustments instead of treating them as roadblocks, ensuring that your manufacturing ERP evolves in the smartest way possible. But it’s important that you’re prepared for adjustments along the way as well.

The discovery stage for a manufacturing ERP system typically takes between 4 to 10 weeks. The complexity of your system determines the timeframe—more intricate requirements mean more time spent defining every detail. Cost also depends on the project scope, ranging from $12,000 to $25,000.

For a detailed breakdown of the timeline, cost, and deliverables, check out our whitepaper.

Once the discovery phase is complete, we’ll confirm a software development team structure with you and get to work. Here’s how it starts:

First, we set up the foundation of your manufacturing ERP system. This means configuring version control, setting up repositories, and establishing development environments. We also put continuous integration and deployment (CI/CD) pipelines in place so every new feature can be tested and deployed efficiently. This step ensures that development kicks off on solid ground, making future updates and scaling much easier.

This is where the designs come to life. Our frontend developers build out every screen, making sure your ERP’s interface is good-looking but also functional and responsive. Every button, pop-up, and interactive element behaves exactly as expected: clicks take users where they need to go, filters work seamlessly in data tables, and layouts adjust smoothly across different devices.

While the frontend handles what users see, the backend powers everything under the hood. Our backend developers build the core logic that processes user actions, manages data, and keeps everything connected. They also set up APIs to integrate your ERP with external tools and services. Performance is a top priority; we make sure the system runs efficiently, even under heavy load.

Quality assurance is a must for a manufacturing ERP; errors in production planning or inventory tracking can cause real-world disruptions. Our QA engineers test each feature as it’s developed, making sure everything works as intended and aligns with your requirements. Any issues get reported back to developers and fixed on the spot.

As features are built, we run regression testing to ensure that new updates don’t break existing functionality. An ERP for a manufacturing company often handles complex workflows, so we double-check that all modules — inventory, production scheduling, supplier management, and more — work together seamlessly.

After testing, we move into stabilization. This process is all about refining and optimizing the system for real-world use. We fine-tune performance, optimize data processing, and resolve any remaining inconsistencies. Whether it’s improving response times for large datasets or ensuring smooth API connections with factory floor equipment, we make sure your ERP is reliable and ready for action.

Here goes another round of testing, but this time, it’s in your hands. User acceptance testing lets your team (or other end users) put the ERP to the test and make sure it fits your workflows. You’ll interact with the system, check if everything functions as expected, and flag anything that needs fine-tuning. Based on your feedback, we’ll make the necessary adjustments before moving forward.

Once the entire system is tested, it’s go-time. We handle deployment setting your ERP for manufacturing in a live environment. During and after launch, we run final checks to confirm everything is working as it should. And that’s when your ERP becomes ready to support your manufacturing operations.

We break ERP development into 2-4 week iterations, each focused on building and refining specific features. Once an iteration is complete, we move to the next, allowing us to stay flexible, catch issues early, and adapt to any needed changes. This approach also helps optimize costs in software development by preventing major rework down the line.

Now, let’s talk about the functionality of a manufacturing ERP.

As we said, features in manufacturing ERPs are tailored to the industry-specific processes. And if it’s custom-built? Even better — it’s designed around your processes. There will be no useless features that only prolong development time and make your ERP clunky. The same principle applies to ERP software for logistics industry solutions, which must handle transportation management, warehouse coordination, and supply chain visibility in one connected system.

Take our client, a construction material manufacturer, UDK, for an example. UDK is a part of a large international corporation of over 2 million employees. Their team faced frequent errors due to manual handling of sales, logistics, and reporting tasks. Some processes required up to six specialists, slowing down operations.

We’ve built a manufacturing ERP solution for them that cut errors by 75% and boosted delivery by 104%. Here’s the functionality that made it happen:

| Functionality | |

| General | Authorization, MFA

Search and filters |

| Admin panel | Dashboard

Client registry Counterparty registry System statistics Notification management User management |

| Client account | Client profile

Notifications News Product catalog Product order placement & details Shipment order placement & details Documentation view |

| Order management | Order list

Order details Order confirmation/ termination |

| Shipment management | Shipment order list

Automated delivery contractor selection Shipment details & tracking |

| Warehouse logistics | Inventory management (considering orders & production schedule)

Calculation of vehicle loading schedule |

| Logistics | Calculation of product delivery schedule

Vehicle composition based on loading/unloading type and delivery points Calculation of optimal order distribution across vehicles Delivery schedule builder for large orders |

| Financial management | Automated invoicing

Payment status notifications Client account balance management, discounts, bonuses, credit limits |

| Document module | Document upload/download

Document storage |

| Integrations | Accounting system

Map services Messenger Email service SMS service |

We streamlined manual tasks by automating workflows and structuring everything into clear, efficient modules. Instead of replacing systems the client was already happy with—like their accounting software—we integrated them into the ERP, enabling seamless data exchange and automating processes like invoicing.

Just like we did for UDK, we’ll shape your ERP to fit your exact needs.

Now, let’s break down the functionalities we’ve built and how they align with our clients’ manufacturing processes.

A well-structured production scheduling and shop floor control module keeps manufacturing operations efficient by optimizing resource allocation, minimizing downtime, and ensuring production stays on track. With real-time visibility into shop floor activities, managers can:

For one of our projects, we developed a factory surveillance system with an intuitive dashboard that streamed real-time data from sensors and security cameras. Automating these monitoring tasks not only helped prevent unauthorized access to sensitive production information and reduce tool and product loss but also freed up supervisors to focus on optimizing production workflows rather than manually overseeing operations.

This module in an ERP for manufacturing includes stock level monitoring, automated replenishment, batch and serial number tracking, and FIFO-based cost management. As a core component of inventory management software, it ensures accurate inventory data, reducing shortages and overstock.

For example, our Strapping project featured real-time stock updates and double synchronization to prevent fulfillment errors — an approach that improves production flow in manufacturing. With automated stock reviews and precise tracking, this module helps optimize inventory costs, streamline order fulfillment, and support seamless production planning.

Keeping production profitable starts with a clear understanding of costs. A robust cost tracking system allows manufacturers to monitor expenses across materials, labor, and overhead in real time. By breaking down costs per job, batch, or product line, businesses can spot inefficiencies, adjust pricing strategies, and improve overall profitability.

For clients needing seamless financial management, we’ve integrated ERPs with existing accounting systems for real-time data synchronization. For instance, we built an integration with NetSuite, enabling automated cost tracking and financial reporting.

In another case, for UDK, we connected their ERP for manufacturing to a custom-built accounting system, ensuring automated invoicing and eliminating manual data entry. These integrations helped streamline financial oversight, reducing errors and saving valuable time.

With real-time monitoring and automated quality checks, this module supports defect tracking, inspection scheduling, and compliance reporting to meet industry requirements.

In the Volan project, we contributed to the development of geofencing visualizations and live mapping functionalities, enabling precise tracking of vehicles and equipment. These capabilities can enhance quality control by ensuring proper handling of materials, monitoring critical processes, and preventing deviations that could impact compliance.

This module lets your team track machinery conditions and schedule routine servicing. By integrating IoT sensors and maintenance logs, you can predict issues before they cause disruptions.

For example, real-time equipment data can be visible right in your manufacturing ERP system and trigger automated alerts for maintenance needs. This approach not only extends asset lifespan but also optimizes production efficiency by reducing unplanned stoppages and costly emergency repairs.

Barcodes speed up scanning, making stock updates instant, while integrating RFID readers with an ERP for manufacturing takes it even further: inventory updates automatically as materials move through production. This cuts errors, keeps inventory accurate, and saves time on the shop floor.

These are just a few examples of what we’ve built — and what we can build for your manufacturing ERP. We’ll tailor every feature to fit your workflow seamlessly and ensure smooth integration with external systems.

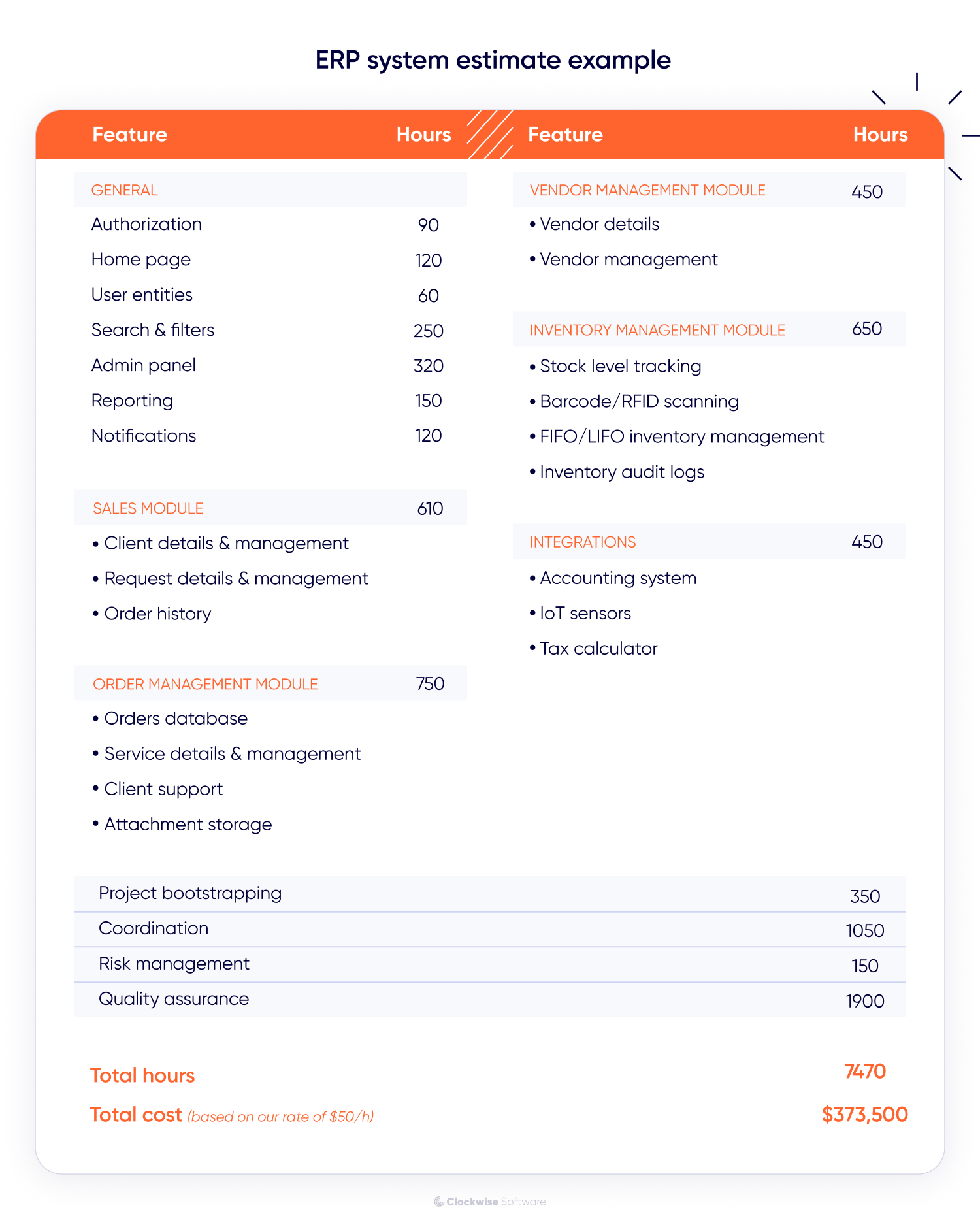

Developing a custom manufacturing ERP system starts at $350,000 and typically takes at least 9 months, depending on the scope. To help you understand what shapes custom software development costs, we’ve broken down ERP functionality with approximate estimates based on our projects.

For systems with broader functionality, costs can exceed $500,000, with development stretching beyond a year.

With our clients, we frequently start with a minimum viable product (MVP). An ERP MVP includes core features and essential modules, providing a functional foundation on which to build. Depending on the scope, developing an MVP costs between $150,000 and $200,000 and takes around six months.

Releasing your manufacturing ERP system isn’t the end of the road. Here starts the next stage, where our team stays on board to ensure your ERP runs smoothly and evolves to meet your needs.

Costs for this stage can vary depending on what you want to tackle and how fast you want it done.

If the scope is small or you’re in no rush, a smaller team can handle it at a steady pace, keeping things more affordable. But if you're aiming for a bigger upgrade or need to implement changes quickly, we’d bring in a larger team to speed up development. That'll push the monthly budget higher, but you’ll get results sooner.

Here’s an example of what a monthly budget might look like based on how we allocate the team.

| Team composition | Monthly budget |

|

$12,000 |

|

$48,000 |

| * On-demand involvement | |

The bigger your manufacturing operation gets, the harder it is to keep everything running smoothly. If your current ERP for manufacturing is slowing down operations, there’s a way to fix it without starting from scratch. It just takes the right improvements designed around how your manufacturing business actually runs.

Take UDK, for example. We built their ERP system years ago, and after nearly a decade, they came back with new challenges. We now make major updates to their system: rewrite with modern frameworks, create a multitenant architecture, and add new features tailored to their evolved processes.

The scale of improvements for your system can vary; the exact scope comes down to the current state of your manufacturing ERP and your goal. You can use software development consulting services to have a technical expert define the optimal ways to improve your system. Here are a few examples of how we help manufacturers upgrade their ERP systems:

A manufacturing ERP is what brings manufacturers from constant firefighting to smooth operations. It eliminates manual bottlenecks, synchronizes workflows, and gives real-time control over production, inventory, and costs. But it’s important to remember that success with ERP is about making it fit your processes, team, and business goals, not just packing it with industry-specific essentials.

We’re ready to help you build the right product. Whether you need a full-scale ERP for manufacturing or a focused solution to fix specific pain points, let’s build a system that moves your manufacturing forward.