AI solutions

What we do

Services

Experts in

How we work

There's no shortage of ERP software out there, but very few are actually built with the construction industry in mind — with its complex workflows, changing schedules, subcontractor networks, and razor-thin margins.

Since 2014, our team has delivered over 200 software projects — and about half of them were either full-fledged ERP systems, specialized modules tailored to existing ERPs, or other business systems. We’ve worked with general contractors, real estate developers, and construction management firms to automate operations, streamline resource planning, and improve project visibility across teams and job sites.

To put this guide together, our ERP development company teamed up with our business analyst and solution architect — both with years of hands-on experience building ERP systems for the construction industry. Here’s what we’ve learned — from the technical approach to the real challenges and costs behind building a construction ERP that actually delivers.

Standard ERP systems can handle generic business operations — accounting, HR, inventory, basic project tracking. But when it comes to the realities of construction — overlapping schedules, subcontractors, complex procurement, compliance, and on-site workflows — most general-purpose solutions fall short.

In this section, we’ll walk you through where general-purpose ERPs hit their limits and why a construction-focused system makes all the difference.

Most general-purpose ERPs are built for industries with predictable workflows — like manufacturing or finance — where operations follow a fixed structure. Construction is different. It’s project-based by nature, with each job site operating as its own ecosystem: separate timeline, budget, team, scope, and risks.

Construction ERP software reflects that. They’re designed to treat each project as the core unit (not just a department or cost center) allowing for accurate tracking, planning, and decision-making at the project level. The same applies to real estate ERP, where each property or development site is a distinct unit. That’s something standard ERPs just aren’t built to support.

Standard ERPs usually treat procurement as a straightforward process: create a purchase order, track delivery, update inventory. That’s often enough for retail solutions or ERP for manufacturing, where purchases are typically tied to stable supplier contracts or internal forecasts.

In construction, it’s different. Every purchase is part of a broader web of contracts, bids, milestones, and external vendors — with tighter timelines, changing scopes, and higher legal and financial stakes.

Industry-specific ERP systems are built around contract-based workflows. They support bid management, subcontractor agreements, milestone-based payments, and compliance tracking — all essential when working with dozens of third-party vendors across multiple projects.

This isn’t just about managing documents. It’s about reducing legal and financial risk by making sure every contract is followed, every requirement is tracked, and every change is documented.

General-purpose ERPs cover the basics — payroll, invoicing, expense tracking — but they rarely go deep enough for the construction industry.

ERP software for construction is built to handle project-based finances in detail. That includes job costing tied to labor and materials, multi-phase invoicing, retention payments, and progress billing — all of which are essential for keeping cash flow steady on long-term projects.

They also support industry-specific needs like AIA billing, WIP (work-in-progress) tracking, and cost variance analysis, giving you a clear picture of where your budget stands at every stage. Without these tools, it’s nearly impossible to manage the financial side of construction efficiently.

Construction comes with a very different set of compliance requirements — far beyond what most general-purpose ERPs are built to handle.

Construction ERP systems are designed to manage job-site safety documentation, track prevailing wages under the Davis-Bacon Act, handle lien waivers, and ensure adherence to environmental and labor union regulations. These aren’t optional checkboxes — they’re critical for avoiding fines, legal disputes, or project shutdowns.

Construction relies heavily on field and design tools, and without integration, the disconnect slows everything down.

A construction ERP is designed to work alongside Building Information Modeling (BIM), CAD systems, estimating software, and scheduling tools. These integrations allow real-time design updates, automated material takeoffs, and faster reactions to changes on site or in scope.

It’s the bridge between the back office and the job site — something general ERPs simply aren’t equipped to handle.

Traditional ERPs are built for desks — not job sites. They assume users are sitting in an office, not climbing scaffolding or managing crews on-site.

Unlike these systems, construction ERP is built with field operability in mind, offering mobile access for real-time data entry, inspections, safety checklists, and material tracking. Whether it’s updating progress from the field or reporting an issue mid-shift, the system keeps site teams and office staff on the same page — without delays or double work.

They’re also designed for on-site decision-making, including document approvals and signatures — so forms don’t sit in someone’s inbox while work stalls on-site. Without mobile access, critical parts of your ERP may go unused — especially in the field.

Ready to see what goes into building an ERP tailored for real job sites, crews, and deadlines? Here’s how we approach it.

We approach development of ERP or construction industry by breaking down the process into 3 stages:

Let’s look at what we do on each stage to deliver exactly what you expect (without budget overruns or timelines that stretch forever). Of course, with insights into optimal choices for core functionality, and cost estimate examples.

Our first stage in focus will be project discovery.

This stage lays the foundation for a system that fits your actual workflows, field realities, and business structure — not one that needs constant workarounds later. Here’s how we make that happen.

We don’t start the project discovery phase with features or tech stacks — we start with exploring how your business actually works.

In construction, that means looking closely at how your teams manage projects, assign resources, coordinate with subcontractors, handle procurement, and track on-site progress. We map out everything: how data flows between departments, where delays happen, and which manual processes eat up the most time. At this stage, we also ask questions like:

These conversations help us understand the full picture — from daily field operations to executive-level reporting — so we can design a system that supports how your projects actually run, without being limited by how traditional ERPs are structured.

With a clear picture of how your construction business runs, we shift to defining what the ERP system needs to support — in practice, not just on paper.

Now it’s time to connect the dots. We take everything your team shared — how you work, what’s missing, and where the gaps are — and turn it into a clear structure for the ERP: what functionality a system should include, how modules interact, where integrations are needed, and what workflows the system should support end-to-end.

We also look at the tools you already use — from estimating and scheduling software to CAD or BIM systems — and figure out how the ERP should fit into your ecosystem.

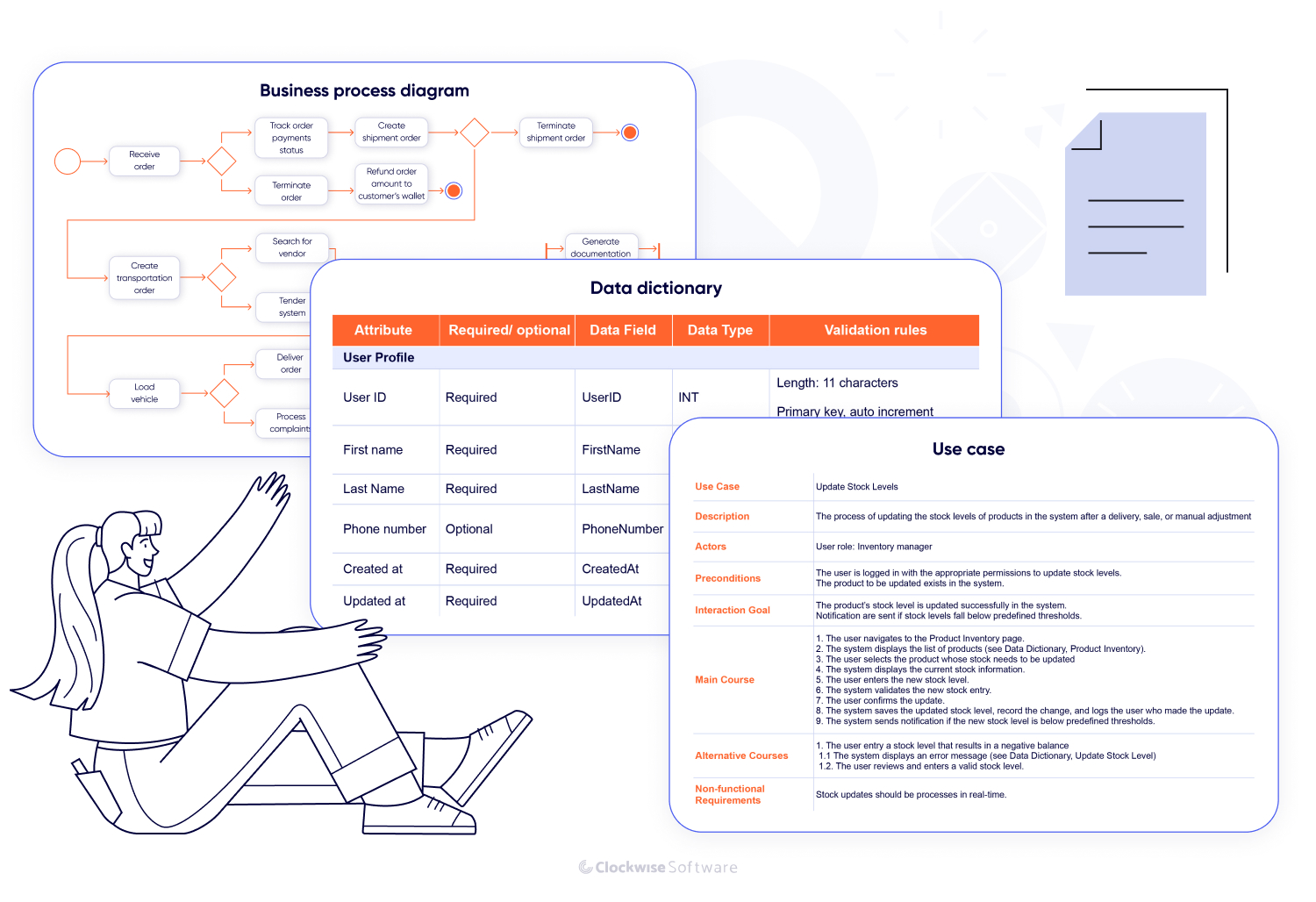

To keep development on track and aligned with your goals, we document the system requirements in detail. That includes:

Business process diagrams that show how work really flows across teams, tools, and departments.

User stories based on your construction workflows that describe how each role will use the ERP in real project scenarios.

Non-functional requirements like security, scalability, and uptime

Wireframes for the full system: dashboards, reports, admin tools, mobile views, and more

This step brings structure to the project and ensures we’re building a system that fits your processes without forcing your team to work around someone else’s logic.

In construction ERP development, ignoring risks early on can lead to delays, rework, and unexpected costs — especially when you're dealing with multiple projects, remote sites, and third-party vendors.

That’s why, during discovery, we take time to identify all types of risks in software engineering upfront. For example, we often see challenges around integrating legacy systems or syncing data from field tools like scheduling apps, BIM models, or IoT sensors used on job sites. Each integration comes with its own constraints — from limited APIs to inconsistent data formats — so we review documentation, run feasibility checks, and define a plan to make everything work.

Data migration is another common risk. Construction companies often manage years of past project data, contracts, invoices, and compliance logs — all stored across different systems (or even spreadsheets). We carefully assess what data needs to be moved, how clean or structured it is, and how we can migrate it without disrupting operations.

For high-risk areas, we may build a proof of concept (POC) of certain modules — for example, to test how well the ERP can pull real-time data from field apps, or whether subcontractor performance tracking can be automated without compromising accuracy. This helps avoid surprises during development and keeps the system aligned with how your teams actually work.

A well-designed construction ERP isn’t judged by looks — it’s judged by how smoothly it works when you're under pressure.

Construction teams often work in less-than-ideal conditions — on a phone in the field, with limited connectivity, or in a trailer juggling multiple updates. That’s why we focus on usability: quick data entry for time tracking, easy access to drawings or safety checklists, and interfaces that work just as well on mobile as on desktop.

At this stage, we take the wireframes built earlier and shape them into a clear, practical interface. That means, for example, designing dashboards that show exactly what a site manager, project accountant, or procurement lead needs to see.

We also build an interactive prototype that lets your team click through real screens before development starts. You can test workflows, spot bottlenecks, so we can make changes to designs early — when it’s still fast and affordable to do so.

Our goal is simple: a system that feels intuitive, so your team can focus on the job, not figuring out how to use the software.

Choosing the right tech stack for a construction ERP is a decision that defines how well the system will support your operations, adapt to future needs, and connect with the tools and equipment you already use.

For most construction ERP solutions, we go with a modern, flexible web-based stack. On the frontend, we use JavaScript frameworks like React or Vue.js to build fast, responsive interfaces your team can use from laptops, tablets, or smartphones — whether in the office or on-site.

On the backend, we typically use Node.js (with NestJS or Express) or Laravel, depending on the complexity of business logic and integration needs. This allows us to create a scalable and secure core that handles everything from project financials and document tracking to real-time status updates from the field.

As for system architecture, we typically use a service-oriented or event-driven approach. That means each ERP module — like asset tracking, procurement, or HR — runs as its own service and communicates with others through APIs or real-time event streams. It also allows us to integrate with on-site hardware or third-party tools without breaking the whole system if something changes.

When it comes to infrastructure, we deploy cloud-first — using AWS, Azure, or Google Cloud — so the system can scale with your business and support multiple job sites without investing in local servers. Tools like Terraform help us automate and manage infrastructure, ensuring cloud based ERP system consistent performance and easier updates.

Security, uptime, and reliability are built in from the start. With encrypted connections, role-based access, and automated backups, we make sure your ERP is protected from common risks in software development — whether it's tracking financials or pulling live data from machines on a remote site.

Once the system architecture, integrations, and design are finalized, we move on to planning the actual development process. At this point, the goal is to break the project into clear, manageable steps, so we can deliver consistently, avoid scope creep, and keep everything aligned with your business priorities.

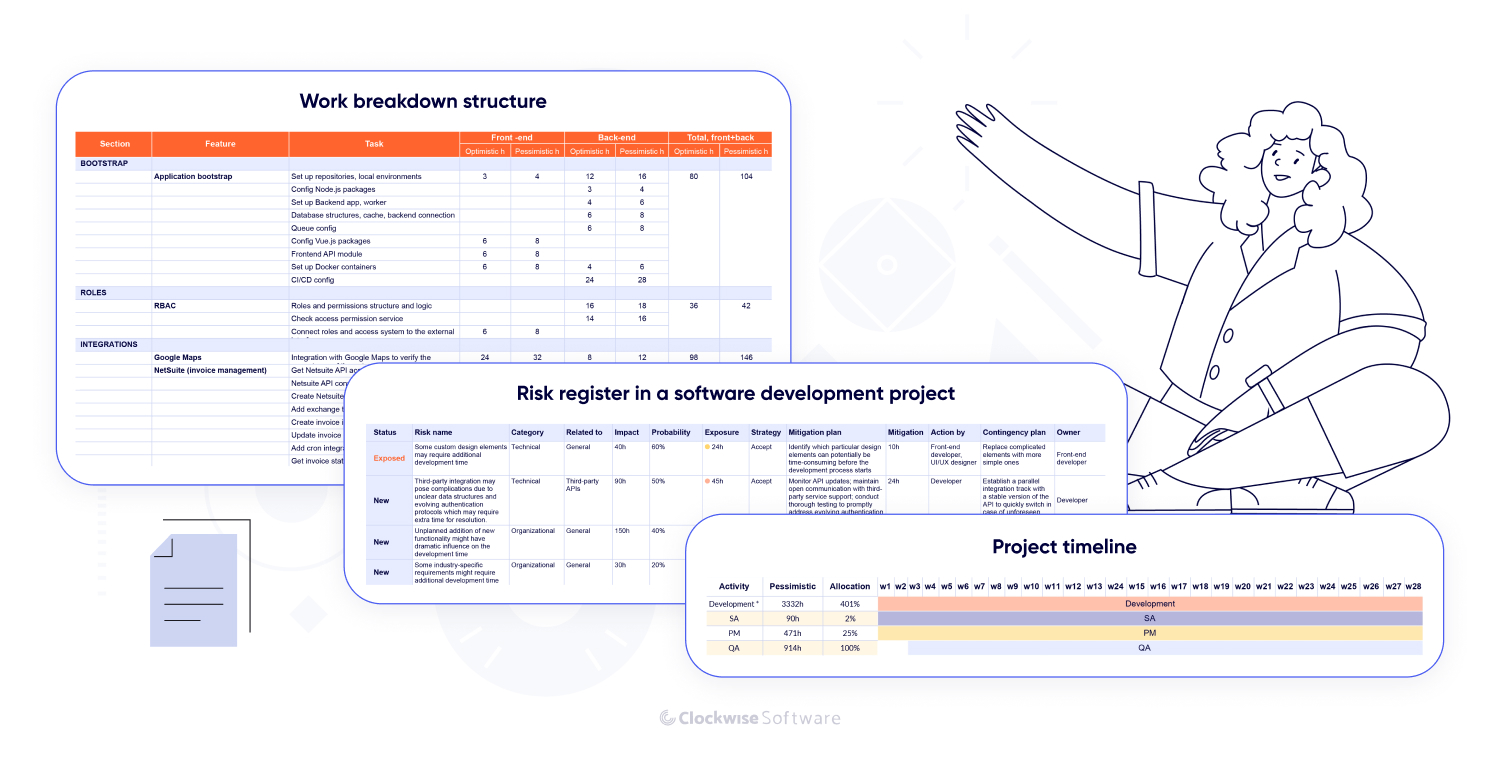

We organize the work into a detailed roadmap, usually broken down into short sprints. Each sprint focuses on building and testing a specific feature set — whether that’s subcontractor management, cost tracking, or mobile tools for site inspections. Here’s what we finalize at this stage:

Work breakdown structure (WBS). A detailed view of the ERP split into modules and tasks, each with realistic and pessimistic time estimates.

Cost estimate. A clear budget based on the scope of work and priorities, so you can make informed decisions.

Risk register. A list of remaining risks — technical or organizational — along with strategies to mitigate them.

Project timeline. A phased schedule with milestones and checkpoints to keep progress transparent.

Team composition. A proposed team structure that fits the workload — from lean setups for MVPs to multi-specialist teams for full-scale platforms.

We keep the development plan flexible — and for a reason. With large systems like ERP, changes are almost guaranteed. Priorities shift, tools evolve, and sometimes what looked right early on needs a rethink.

That’s why we build both realistic and pessimistic estimates from the start, and keep the plan adaptable. If changes come up, we’ll re-evaluate the scope and timeline together — transparently and with full context — so you can make informed decisions.

We’ll do everything to keep surprises out of the process, but it helps when both sides treat the plan as a guide, not a fixed promise. Flexibility is what keeps the whole thing moving.

The discovery stage typically takes between 4 and 10 weeks — depending on how complex your operations are. That includes the number of workflows we need to map, the level of feature depth required, and how many systems your ERP needs to integrate with or replace.

For example, discovery for a company handling a few residential projects per year with basic reporting needs will move much faster than for a commercial builder managing dozens of sites, multiple subcontractors, and strict compliance workflows.

The cost of discovery usually falls between $12,000 and $25,000, depending on the scope. At the end of discovery, you’ll have a clear roadmap for building your ERP — with system requirements, architecture decisions, and risk mitigation already in place.

With that foundation, we move into development — turning plans into a working system, one module at a time.

The focus now is on building, testing, and refining your construction ERP system module by module. We start with project bootstrapping: setting up infrastructure, code repositories, development environments, and CI/CD pipelines to keep delivery processes efficient and automated from day one

Then we move through the core development steps:

Frontend development: Our team turns UI/UX designs into a working interface, with clear navigation, mobile-friendly screens, and fast access to project dashboards, field reports, or financials. Whether your team is in the office or on-site, the system needs to feel fast and respond quickly.

Backend development: This is where your business logic lives. We build the entire logic behind modules — from project costing and contract workflows to subcontractor management and compliance tracking — and integrate the ERP with third-party tools like accounting platforms, BIM software, or IoT systems on job sites.

Testing and stabilization: We run QA in parallel with development, validating features as they’re built. After the core system is ready, we move into regression testing and performance optimization to make sure the ERP runs smoothly under real project loads.

User acceptance testing (UAT): Your team steps in to test real workflows. If something doesn’t feel right or isn’t aligned with daily operations, we fine-tune it before release.

Deployment: We set up the production environment, configure monitoring and backups, and make sure all integrations are stable. Before going live, we run final checks to confirm everything works as expected in the real setup. Once your ERP is launched, we’re right there with you — helping your team get started and resolving anything that might come up along the way.

We typically work in 2–4 week sprints, giving you regular updates and progress demos. This approach keeps the project on track while giving you the flexibility to adapt as your business needs evolve.

A well-built ERP system doesn’t need a thousand features — it needs the right ones. In construction, that means functionality that directly supports your project delivery, controls costs, reduces delays, and keeps your teams in sync.

Here are the core modules we recommend based on what’s consistently delivered value across our construction ERP software projects:

This module sits at the core of any ERP system for construction industry. It gives your team full control over active and planned projects — from scheduling and milestone tracking to handling change orders and task dependencies.

With everything in one place, project managers can monitor progress in real time, allocate resources more effectively, and quickly react to delays or scope changes. Instead of juggling spreadsheets and disconnected tools, you get a system that keeps everyone — from field teams to execs — on the same page.

We implemented similar functionality for a municipal company in Ireland. The system supported complex project tracking with role-based access controls, ensuring that each internal team had access only to the data relevant to their responsibilities. This not only improved security but also simplified day-to-day collaboration across departments.

Every project has its own secure space for documents, so blueprints, contracts, and permits are always easy to find and update—no more digging through emails or folders.

We built a similar setup for Renomate, a Swedish company focused on apartment construction and renovation. By keeping all project documents together with cost estimates and schedules, their team always knew where to find the latest info with no more searching or second-guessing.

Keep all your external partnerships on track. This module helps you create and manage contracts, track subcontractor work, handle compliance by tracking certifications and insurance, and automate purchase orders—all in one place.

You can compare supplier prices, manage approvals, and align material orders with your project schedules, making it easier to avoid delays and control costs. With everything organized together, you get clear oversight and stronger vendor relationships without extra busywork.

We built a similar system for Vialoop, a SaaS platform designed to manage maintenance operations with a large vendor network. The platform automates the full contract-driven workflow: from receiving job requests and matching them with qualified vendors, to handling documentation and final settlements. Every step — from assignment to compliance verification — is backed by structured data and clear audit trails, making it easier to maintain transparency and enforce agreements.

In construction, financial tracking needs to be project-specific — down to each job, phase, and crew — not just overall revenue and expenses. This module is built to handle that complexity.

It centralizes everything from job costing and budget tracking to multi-phase invoicing and progress billing. You can monitor real-time spend against budgets, manage retention payments, and stay on top of financial obligations as projects evolve.

Support for AIA billing, WIP (work-in-progress) reporting, and cost variance analysis gives your finance team the visibility they need to manage cash flow, forecast risks, and protect profit margins — all without jumping between disconnected spreadsheets or systems.

In construction, compliance is daily, detailed, and often high-stakes. This module centralizes everything from OSHA tracking and safety audits to subcontractor compliance, insurance documentation, and environmental reporting.

It helps teams stay ahead of issues with automated incident reporting, real-time non-compliance alerts, and scheduled safety checks. Worker certifications, insurance expiration dates, and subcontractor documentation are all tracked in one place, reducing the risk of delays, fines, or site shutdowns.

By integrating risk assessments and mitigation planning directly into project workflows, this module helps your team identify and respond to issues early.

Coordinating workforce schedules and payroll across multiple job sites is a major challenge in construction — especially when you’re dealing with union rules, multi-rate pay, and shifting project demands. This module brings it all under control.

It covers time tracking, shift scheduling, biometric attendance, and payroll automation with full support for prevailing wage calculations, certified payroll reporting, tax deductions, and union wage compliance. Integration with accounting systems ensures payroll data flows directly into your financials — no duplicate entry, no loose ends.

We tackled similar challenges in the Trident project, where we rebuilt a mobile app for field workers to track their hours and job site locations more accurately. Alongside the iOS and Android versions, we integrated the platform with QuickBooks Online — allowing financial data from the field to feed directly into the admin dashboard, giving leadership a real-time view of labor costs per project.

Keeping materials flowing across job sites without waste or delays is critical — and nearly impossible to do manually at scale. This module gives construction teams the tools to track inventory levels, manage stock across warehouses, and monitor material usage on-site in real time.

It supports automated reordering, barcode and RFID scanning, and inventory forecasting based on project timelines. You can track what’s in stock, what’s been delivered, and what’s at risk of running out — all in one dashboard.

It leads to fewer shortages, less overordering, and better coordination between procurement, warehouse staff, and site managers. It’s the difference between always playing catch-up and running a smooth, predictable operation.

Managing heavy equipment, vehicles, and tools across multiple sites requires more than just a checklist. This module is built to track asset assignments, monitor usage, and schedule maintenance — reducing downtime and preventing expensive losses.

It includes real-time GPS tracking, route history, and fuel usage monitoring, helping your team optimize logistics and reduce unnecessary wear. You’ll always know where each asset is, who’s using it, and when it’s due for servicing.

We’ve implemented similar functionality in the UDK WebOffice project — a custom system for a building materials manufacturer. One part of the solution focused on route planning and delivery coordination, helping the company increase daily truck utilization from 45 to over 90. The same approach can be used here to track equipment movement between sites and optimize asset deployment across your projects.

One of the biggest advantages of a construction-specific ERP is its ability to bridge the gap between design and execution.

This module connects your ERP with key industry tools — including BIM platforms, CAD software like AutoCAD and Revit, and scheduling tools like Primavera P6 or Microsoft Project. Design changes made by architects or engineers can be automatically reflected in procurement plans, material orders, and construction schedules.

This level of integration reduces manual rework, minimizes miscommunication, and helps field teams act on the latest design updates without delay. It turns your ERP into a real-time coordination hub and not a backend system disconnected from what's happening on the job site.

Construction work doesn’t happen behind a desk — and your ERP shouldn’t expect it to.

This module brings full ERP functionality to the field with mobile and cloud-based access, allowing site teams to report progress, fill out safety checklists, submit timesheets, and track equipment directly from their phones or tablets. Whether it’s logging an issue, confirming a delivery, or updating project milestones, everything can be captured in real time.

Offline access ensures the system stays usable even in remote areas or during network outages, syncing data automatically once the connection is restored. The result is tighter coordination between job sites and HQ, faster decision-making, and fewer delays caused by paperwork bottlenecks or missing information.

Without the right data, managing construction projects becomes a guessing game. This module brings together real-time dashboards and automated reports to give your team full visibility into every part of the operation — from project performance to financial health.

You can get detailed insights into job costing, retention payments, WIP status, equipment downtime, labor hours, and material usage — all in one place. Tools like earned value analysis help you track actual progress against budget and schedule, so you can spot issues early and make informed decisions.

By centralizing reporting, this module eliminates time-consuming manual updates and ensures stakeholders always have access to accurate, up-to-date information — whether they’re on-site or in the boardroom.

Every module above is based on what we’ve seen work — across our ERP builds for general contractors, developers, and project managers. That said, your system doesn’t need to include everything listed above. It might cover just a few core modules, or focus on something different — like equipment tracking, subcontractor management, or advanced compliance tools.

That’s the point of building a custom ERP: we don’t force you to work around pre-built templates. Instead, we shape the system around your workflows, priorities, and the way your teams actually operate.

Now, let’s talk about the part everyone asks while choosing a software development partner — how long building an ERP takes and what the investment looks like.

The cost and duration of a construction ERP project depend heavily on your system’s scope — how many modules you need, which third-party tools it should integrate with, and how complex your workflows are.

On average, a minimum viable version (MVP) with core features — such as project management, budgeting, subcontractor coordination, and field reporting — typically takes around 6 months to build and costs between $150,000 and $200,000.

A full-scale ERP that includes advanced functionality like BIM integrations, equipment tracking, payroll automation, and compliance management can take 9–12+ months to develop. Cost of custom software development for systems at this scale usually starts at $350,000 and goes higher depending on the level of customization and team size required.

Here is a rough estimate example:

If your priority is to launch faster and validate the system with a limited rollout, starting with an MVP is often the best approach to minimize risk, reduce software development costs, and create space for gradual scaling based on real-world usage.

Post-release support can be flexible — whether you're fixing edge cases, optimizing performance, or rolling out new features based on user feedback.

Depending on your pace of growth, this can mean a small team handling occasional updates or a larger crew managing upgrades, new functionality, and faster iteration cycles.

The size and cost depend on how actively you plan to evolve the system. Here are two examples of support setups:

| Team composition | Monthly budget |

|

$12,000 |

|

$48,000 |

| * On-demand involvement | |

Both options are flexible. We can scale the team up or down as your needs change — without long hiring cycles or underutilized full-time staff.

If you’re already using an ERP system but feel like it’s not keeping up with your business — you’re not alone.

We often hear from construction companies that their current ERP was either too generic from the start or hasn’t scaled with the way their operations have grown. Maybe it can’t support your current project volume. Maybe it's missing key features like equipment and material tracking, mobile field reporting, or BIM integration. Or maybe it just feels clunky — forcing your teams to work around the system instead of with it.

That’s where our software development and consulting company can help.

We don’t jump straight into development. We start with a focused discovery process: reviewing your existing setup, identifying what works, spotting what’s slowing you down, and mapping out the best way to move forward — whether that means expanding the system, replacing outdated modules, or integrating new tools.

Our job isn’t to sell you a new ERP from scratch — it’s to make sure you get the system your team actually needs, with minimal disruption and maximum value. With years of experience modernizing construction software, we know how to work with legacy systems, preserve what’s useful, and upgrade what’s holding you back.

If you’re not sure where to start, let’s talk. We’ll help you figure out what’s possible — and what’s worth building.

If there’s one thing we’ve learned from seeing our clients’ results, it’s this — your ERP has to reflect how your team really works. Templates won’t cut it. The right system fits your operations, not the other way around.

At Clockwise Software, we spent years helping construction companies do just that. From end-to-end systems to targeted modules and integrations, we build solutions that support how work really gets done — in the field, at the office, and everywhere in between.

Whether you’re starting from scratch or thinking about improving the system you already have, we’re here to help, making project delivery smoother, more predictable, and less wasteful.