AI solutions

What we do

Services

Experts in

How we work

If your ERP wasn’t built for supply chain complexity, it shows. Missed handoffs, supplier delays, inventory guesswork — it all adds up fast. Generic ERP platforms just can’t keep up when real-time coordination and external collaboration are core to your business.

At Clockwise Software, we’ve seen it firsthand. Since 2014, we provided ERP software development services and built systems and modules that sharpen supply chain visibility, automate complex workflows, and connect operations in real time, from logistics coordination and fleet management to inventory tracking and financial reporting.

This guide was put together with input from our business analyst and solution architect, the same people who map out ERP projects for our clients. No fluff; just a clear look at how we approach supply chain ERP development, what features really matter, and what to expect in terms of time and cost.

Many ERP systems include supply chain modules, but they’re usually built around internal structure, not real-world coordination. When your business depends on syncing suppliers, warehouses, and production in real time, those generic setups often can’t keep up.

A supply chain ERP connects the entire flow, from purchase orders to delivery, across locations, suppliers, and platforms. It gives you the visibility, speed, and control generic systems just don’t offer.

Here’s where that difference really matters.

ERP software for supply chain management is built to support day-to-day movement: of goods, data, and decisions. It tracks inventory across locations, syncs POs with production, coordinates deliveries, and helps your team react when demand shifts or disruptions hit. It’s built around real operations, not just record-keeping.

Standard ERPs focus on internal admin. They’re solid at managing finance, HR, and payroll, but they often aren’t designed for the pace or complexity of a modern supply chain. And when coordination breaks down outside the office, that internal focus becomes a real liability.

ERP in supply chain systems are made for pace and pressure. They handle thousands of SKUs in motion, hourly stock shifts, last-minute supplier changes and help your team act on it all in real time. It’s not just about storing data, it’s about responding fast when plans change.

Most ERPs aren’t built for that. They assume steady workflows and predictable cycles — great for month-end reports, not for managing disruptions in a high-volume, high-variability environment. When things move fast, those assumptions turn into bottlenecks.

ERP in supply chain management is built to connect, not just internally, but across your entire network. They integrate with WMS, TMS, barcode scanners, supplier portals, even IoT and blockchain systems when needed. And they don’t stop at collecting data, they automate the flow: routing orders, syncing inventory, tracking deliveries, and triggering updates in real time.

General ERPs can’t keep up with that level of sync. They’re built for consistency, not speed, often missing support for high-frequency updates, hardware integrations, or event-driven workflows. That gap turns into manual work, missed updates, and decisions made after it’s already too late.

Supply chain ERP management software isn’t tied to a single industry. It’s built around how supply-driven businesses actually work, whether that’s global sourcing, regional distribution, or multi-site production.

Where standard ERPs aim to cover broad business functions, such as HR, finance, general ops, supply chain ERP focuses on the roles and processes that keep goods and data moving. It’s made for the people managing inventory, coordinating with vendors, adjusting to delays, and making real-time decisions under pressure.

It’s not about what industry you’re in, it’s about what you move, how fast it needs to move, and who’s responsible for keeping it all on track.

Generic ERP can’t catch up to supply chain speed, but a system built the right way can. Here’s how we design, build, and deliver supply chain ERP that’s ready for real-world operations.

Supply chain software development services usually follow three core stages:

We’ll walk you through what each stage looks like and what kind of timeline, scope, and investment to expect.

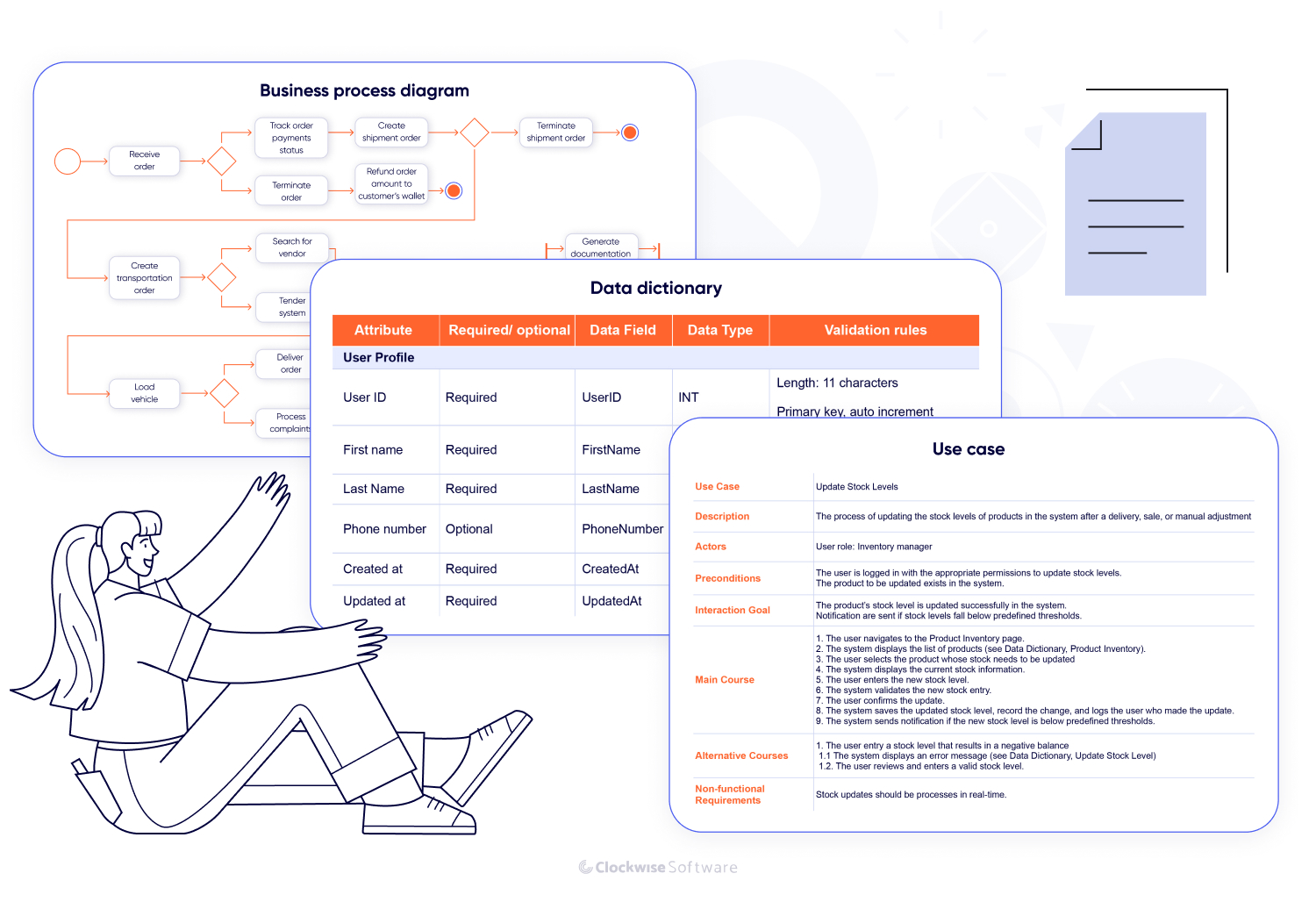

Project discovery is where we step back and map how your supply chain really operates, not how it looks on paper, but how teams, tools, and data actually connect.

We focus on the flow between departments and systems, identify where things break or slow down, and define what your ERP in supply chain management needs to support. It’s how we avoid building around assumptions and start with a system plan grounded in reality.

We don’t start with features, we start with how operations actually run. That means looking closely at how your teams move goods, track stock, manage vendors, and handle last-minute changes. We go beyond org charts and documents to understand how workflows really function. That helps us spot disconnects, surface edge cases, and build a system that fits how your supply chain actually moves.

We map how decisions happen, where data flows (or stalls), and which steps still rely on spreadsheets and email threads. Our team is here to understand how things really work, so the system we build fits into your process, not the other way around.

Once we’ve mapped how your supply chain actually runs, we turn that into a practical system plan.

We define what your ERP in supply chain needs to cover: multi-tier procurement, supplier coordination, inventory visibility across sites, demand planning — everything your teams touch day to day. Then we layer in the connections: customs systems, 3PL platforms, marketplaces, EDI, carrier APIs.

We also lock in the operational logic: lead times, safety stock levels, approval flows, traceability requirements. All of this gets documented in detail: user stories, data flows, integration logic, and business rules, so there’s no ambiguity when development starts. This documentation becomes the blueprint for the entire project: it aligns the team, reduces back-and-forth, and helps keep timelines and budgets on track.

ERP projects for supply chains involve tight coordination across systems, suppliers, and workflows, and if you skip over the risks early on, they’ll catch up fast. From real-time data flows to external integrations and messy legacy systems, small oversights can turn into major setbacks later.

One of the big ones? Integration blind spots. If your ERP in supply chain management needs to talk to customs systems, 3PL platforms, carrier APIs, or supplier portals, and those systems have outdated formats, vague docs, or flaky endpoints, it can derail the whole build. We catch that early by reviewing specs, testing connections, and flagging what’s realistic versus risky.

Data quality is another. A lot of teams are still juggling spreadsheets, siloed tools, and inconsistent naming conventions. Copying that straight into a new ERP causes more problems than it solves. We check what’s worth migrating, what needs cleanup, and how to avoid disruptions when you flip the switch.

We also look at workflow disconnects, like when procurement and warehouse logic don’t align, or when 3PL handoffs get lost in translation. These are the small cracks that turn into big headaches later, so we map them out and fix them before they’re baked into the system.

For high-risk features like customs syncing or inbound tracking, we often build a small proof of concept first: a quick technical test to confirm it’s feasible before investing time and budget.

No one in your supply chain has time to click around and guess. Planners, buyers, warehouse leads, and suppliers need to get in, get info, and get on with it.

That’s why we design around your workflows, not trends. Whether it’s a supplier dashboard, stock transfer screen, or order view, every interface is mapped to what your team actually does. Fewer steps. Cleaner layouts. No confusion.

We also tailor views by role. A warehouse manager doesn’t need the same dashboard as a procurement lead, so we keep each screen relevant, not overloaded.

Before development starts, we build a clickable prototype. Your team gets to test it early, flag what’s clunky, and help shape the final version while changes are still quick and cheap.

We build on a stack that supports speed, clarity, scalability, and clean connections across your entire supply chain network.

On the frontend, we use JavaScript frameworks like React or Vue.js to create fast, responsive interfaces. Whether your team is on the warehouse floor or managing operations remotely, the system works smoothly across all devices, not just behind a desk.

On the backend, we typically use Node.js (with Express or NestJS) or Laravel, depending on your business logic and data model. For databases, we usually go with PostgreSQL or MySQL, solid picks for structured data like orders, inventory, and finances. If your system handles flexible formats (like logs, configs, or custom records), MongoDB fits better. We choose based on how your data behaves, not just what’s popular.

We build ERP systems on modular, scalable architectures, often using microservices or well-structured monoliths, depending on the project scope and priorities. If fast delivery matters more than future flexibility, a monolith makes sense. If long-term adaptability tips the scale, we go with microservices.

Infrastructure is always cloud-first, with deployments on AWS, Azure, or Google Cloud. We automate provisioning with tools like Terraform or CloudFormation to keep cloud-based ERP environments consistent and easy to manage.

You get a system that keeps operations connected, data flowing, and decisions moving, even when demand spikes, suppliers delay, or plans shift last minute.

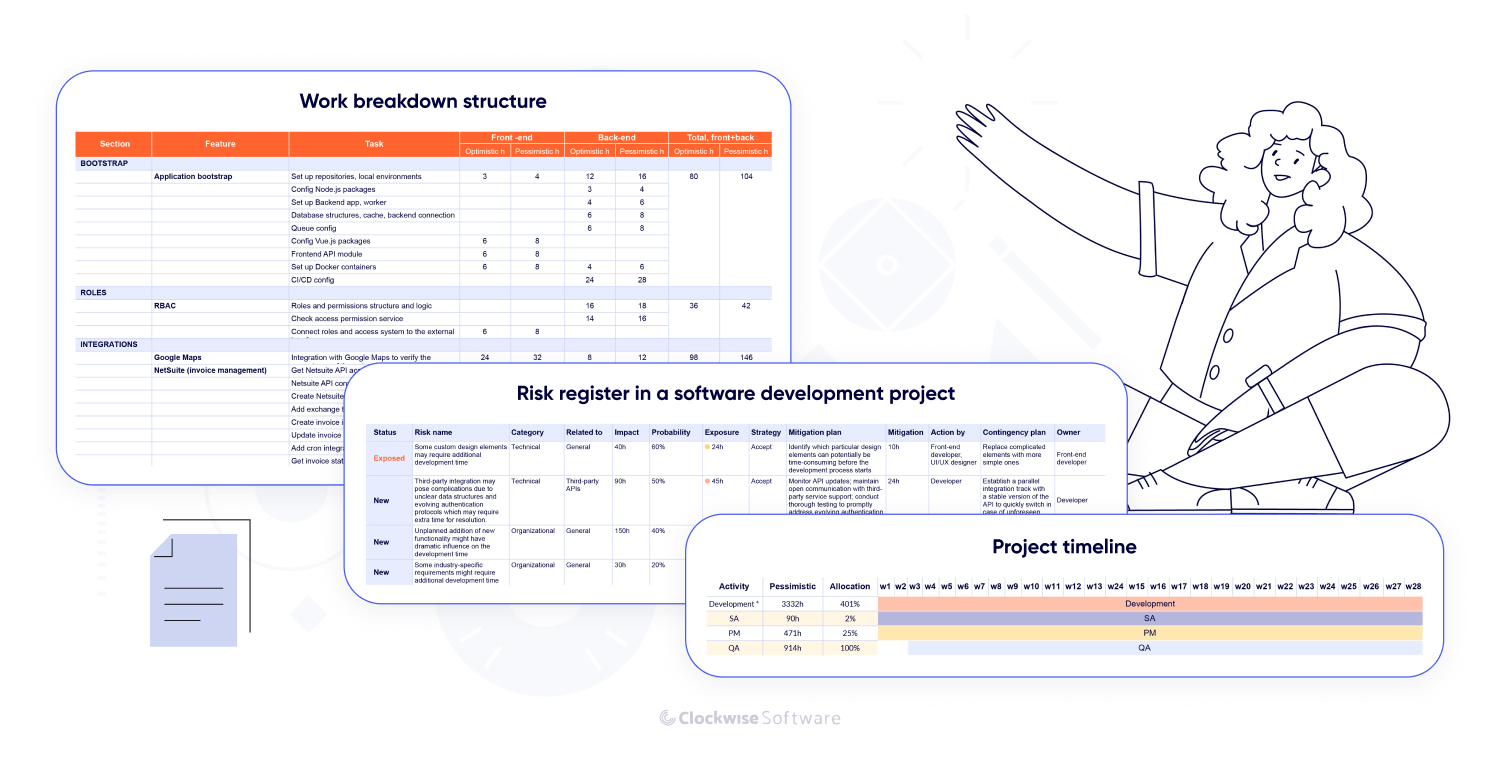

Once the architecture, core integrations, and designs are set, we move into planning, structuring development to stay lean, focused, and aligned with what your operation actually needs.

We build a phased roadmap based on your priorities, mapping out which modules come first, which integrations are critical, and where flexibility is needed if priorities shift later. This phased approach works equally well for logistics, retail, or ERP for food industry solutions.

Before coding starts, you’ll have a full set of deliverables:

Detailed work breakdown structure (WBS) with realistic and pessimistic estimates

Phased roadmap, aligned with your priorities

A detailed cost estimate based on scope, adjusted only if priorities shift or new features are added.

Risk register covering potential technical and organizational issues

Project timeline with a right-sized team, optimized for focused MVP delivery or multi-stream feature builds.

Before we move from planning to development, there’s one reality worth flagging: priorities shift and that’s normal, especially for large projects like ERP systems. We factor that in from the start, keeping scope flexible, estimates realistic, and timelines with breathing room where needed.

What matters most is staying aligned. If something changes, we’ll flag it early, explain the tradeoffs, and work with you to adjust without sending the whole plan off the rails.

The discovery phase for a supply chain ERP usually takes 4 to 10 weeks. Simpler workflows? You’re on the shorter end. If you’re juggling multiple warehouses, hundreds of suppliers, or complex integrations (customs, 3PLs, marketplaces), we’ll need more time to map it out properly.

Expect the cost to fall between $12,000 and $25,000, depending on how many workflows we’re covering and how deep we need to go with integration planning and requirements.

Whether you build with us or pass it to your internal team, you’ll leave discovery with a clear, execution-ready plan, not just ideas on paper.

Once discovery wraps, we shift into full development, sprint by sprint, module by module, following the plan we built together. Here’s how it plays out.

We set up everything needed to start custom software development the right way: cloud infrastructure, version control, CI/CD pipelines, environment configurations, basic security — the foundations that keep delivery smooth, testable, and scalable from the first sprint onward.

Our frontend team builds the ERP in supply chain interface based on the approved designs and workflows. Every screen is built to serve specific supply chain roles, from purchasing leads reviewing incoming POs to warehouse managers tracking multi-location inventory. Everything is responsive, mobile-ready, and designed for daily use in fast-paced environments.

This is where the real logic lives. We build all the core functionality and integrations, from procurement workflows and vendor scoring to API connections with 3PLs, customs platforms, or marketplaces. The backend handles data sync, business rules, and automated processes across the entire supply chain.

Testing happens in parallel with development. Our QA team checks each feature against the documented requirements, making sure what’s built actually matches what was planned. We test logic, edge cases, and process flow to catch issues early and keep the system aligned with how your supply chain operates. After development wraps, we go through full regression testing, fix edge cases, and fine-tune performance.

Now it’s your team’s turn to test the system. Your team runs real workflows through the system (tracking orders, updating inventory, approving invoices) to make sure it works as expected. If something’s clunky or misaligned with your process, we adjust it. This phase helps prevent workflow friction after rollout.

We prepare the production environment, configure every integration (carriers, customs, accounting, etc.), set up monitoring and backups, and carefully migrate existing data into the new system. We run final checks to make sure nothing breaks under load, then roll the ERP out in phases or across the entire operation, depending on the rollout plan.

Supply chain systems touch everything: vendors, inventory, transport, payments, so a failed deployment isn’t an option. That’s why we stay hands-on through launch, closely monitoring performance and resolving issues in real time.

Next, let's break down the essential ERP in supply chain modules that actually move operations forward, based on what we've seen work across multiple projects.

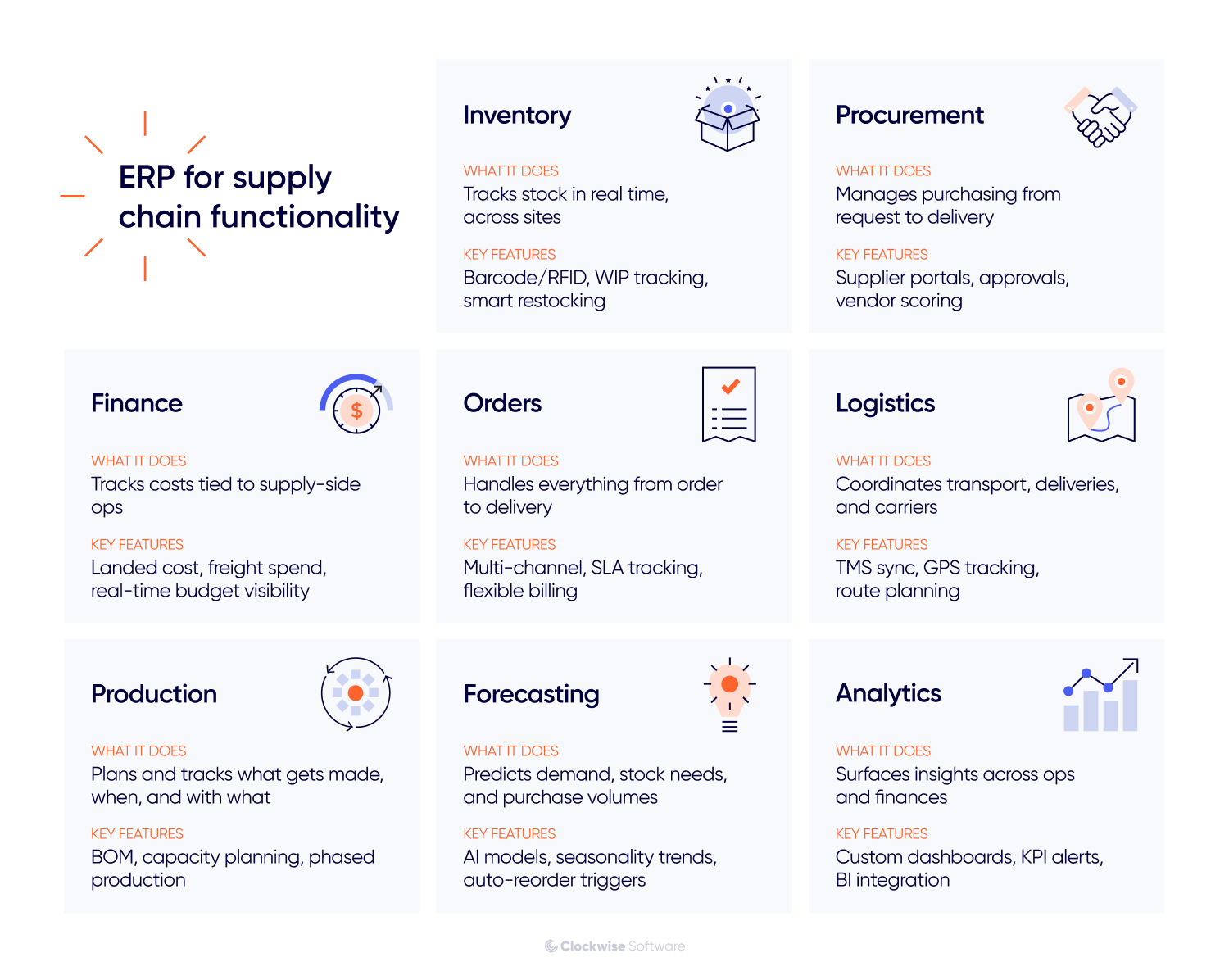

Supply chains run on timing, coordination, and visibility and your ERP in SCM should support that. These are the modules we’ve seen deliver real value across projects in manufacturing, distribution, logistics, and procurement.

This module anchors the entire ERP software supply chain management. It gives your team real-time visibility into stock across all locations, so you can avoid stockouts, reduce overordering, and automate replenishment where it matters most. It connects directly with procurement, orders, and production, keeping everything moving in sync.

For logistics and retail businesses, we can add barcode or RFID scanning, automate warehouse updates, and support multi-client inventory tracking. Manufacturers benefit from tighter production alignment, with raw material tracking, WIP monitoring, and smarter handoffs to reduce downtime and waste.

To put structure around your purchasing process, from initial requests to final payments, you need this module. It helps you manage supplier relationships, approvals, contracts, and delivery schedules without letting things fall through the cracks. Everything connects with finance and inventory to avoid delays, overspending, or missed handoffs.

For manufacturers, retailers, and distributors, it keeps supply steady and aligned with demand. For procurement service providers, we can layer in analytics, supplier scoring, or vendor portals. And in industries with long lead times, like construction or energy, we tailor it to handle volume purchasing, multi-location coordination, and strategic sourcing.

If purchasing plays a central role in your operation, this module brings clarity and control to the entire cycle.

This module gives your finance team a clear line of sight into supply-side spending. By tying together procurement, inventory, and logistics data, it helps track costs in real time, so you can spot overruns early and keep your budget on track.

We also tailor it for freight analysis and landed cost calculations, especially for logistics and manufacturing businesses. That way, you’re not just tracking department-level expenses, you’re understanding true cost per shipment, route, or supplier.

When your financial data and supply chain workflows are aligned, it’s easier to make fast, informed decisions and avoid last-minute surprises.

If your business runs on inventory, shipments, or orders, this module is essential. It centralizes every step, from order creation to fulfillment, and keeps everything in sync with inventory, shipping, and invoicing. No more status guesswork or switching between disconnected tools.

In eCommerce and retail, we often build in multi-channel support, order splitting, and storefront integration. For logistics providers, we tailor features like SLA tracking, client-specific flows, and flexible billing logic.

For instance, in our work with Strapping, we built an order tracking module that mapped every stage, from receiving goods from suppliers to final delivery, ensuring full visibility and fewer handoff errors.

This setup brings clarity to your order workflows and keeps operations aligned, even when the volume ramps up.

Whether you're moving raw materials, finished goods, or anything in between, this module keeps deliveries on track and prevents breakdowns across logistics.

It handles core tasks like shipment scheduling, carrier assignments, delivery updates, and tight integration with your warehouse and order management systems. Everything’s connected and traceable in real time.

During logistics software development, we tailor this module to your needs. For logistics providers, that might mean GPS tracking, dynamic route planning, and fleet coordination. For manufacturers or retailers, it often includes TMS integration, scheduling for outbound loads, and tools to manage delivery timelines across regions.

For example, in a route planning software project, we built real-time route planning that factors in hazards, vehicle types, and live traffic, helping dispatchers avoid delays and delivery risks.

For a fleet management platform, we made dispatcher-driver coordination faster and clearer, cutting mistakes across different delivery stages.

If your business relies on moving goods efficiently, this module ensures nothing gets lost in transit, operationally or digitally.

This module helps manufacturers stay ahead of demand, avoid bottlenecks, and align production with what’s actually happening on the ground.

It connects inventory, procurement, and the shop floor into one flow. Your team can schedule jobs, track progress against your Bill of Materials, and adjust production based on current stock levels or open orders, using supply chain management manufacturing ERP software.

For advanced workflows, we can build in capacity planning and WIP tracking across multiple stages. In prefab construction, we adapt it to coordinate phased builds and timed deliveries to job sites.

This way, production runs with fewer surprises and a whole lot less manual juggling.

Whether you're managing product demand, raw material flow, or procurement volumes across multiple clients or locations, this module gives you visibility to plan smarter. It’s especially useful for manufacturers, retailers, energy providers, and procurement consultants handling large or variable order streams.

It pulls from your historical sales and inventory data to generate forecasts that help you avoid overstocking, prevent shortages, and make timely purchasing and production decisions. The system plugs directly into your inventory and procurement tools and can be enhanced with AI models for more accurate projections when needed.

For manufacturers and retailers, we often include seasonality insights, category-level forecasting, and automated restocking triggers. For multi-client platforms, we design dashboards that support multiple forecasting scenarios side by side.

When timing is everything, this module helps your team stay ready, not reactive.

This module turns operational data into clear insights your team can act on. It tracks the KPIs that matter most across the supply chain, inventory turnover, cycle times, supplier performance, fulfillment delays, and cost variances, all in one place.

We tailor dashboards and reports around how your team works. Need to filter by supplier, location, or product line? Easy. Want reports in formats your finance or ops teams already use? Done, no manual reformatting. We can also set up real-time alerts for low stock, missed SLAs, or budget overruns, so issues get flagged early, not after the fact.

In a project for a telecom-focused BPO platform, we helped automate data consolidation across multiple systems, revealing a €80K gap hidden in inconsistent reporting. Similar automation can help supply chain ERPs surface financial inefficiencies before they spiral.

For teams that need deeper visibility, we integrate with BI tools or embed predictive analytics, helping you surface trends, flag inefficiencies, and plan smarter across operations.

You’ve seen what goes into building supply chain management in ERP. Now let’s break down how long it takes and what kind of budget you should plan for.

The duration and cost of product development for ERP supply chain management projects depend on how complex your workflows are, how many modules you need, and what integrations are required, especially if your system needs to sync with 3PLs, customs platforms, or external vendor tools in real time.

If you're starting with an MVP, expect a 6-month build focused on the essentials: inventory tracking, order processing, basic procurement, and reporting.

That version typically costs $150,000–$200,000 — enough to validate workflows and start seeing value fast, without building everything at once.

A full-scale ERP that covers all critical operations, like demand forecasting, multi-site warehouse management, or deep TMS/WMS integrations, takes 9–12+ months, with budgets starting at $350,000–$500,000+ depending on complexity.

If speed matters, we can start with a lean MVP and scale from there, without cutting corners where it counts.

Getting your ERP in supply chain live is just the start. Keeping it useful and ready for whatever’s next takes the right kind of support. We can stay involved after launch, helping you adapt, expand, and improve without slowing your team down.

Some companies need light support: bug fixes, small upgrades, system monitoring. Others want to hire a dedicated development team and keep pushing forward: rolling out new modules, improving workflows, or adding new integrations as operations grow. Either way, we scale our team to fit what you need.

Here’s what typical support setups look like:

| Team composition | Monthly budget |

|

$12,000 |

|

$48,000 |

| * On-demand involvement | |

Want to plug in a new 3PL? Build out a supplier portal? Fix how forecasting actually drives reordering? We’ll help plan it, ship it, and keep it running.

Got an ERP system in supply chain management that used to work, but now struggles to keep up? You’re not the only one.

Maybe it can’t handle multi-warehouse inventory. Maybe your 3PL partners are stuck outside the system. Or maybe it was never really built for the way your supply chain operates today.

We’re ready to help you improve the ERP you already have, whether that means adding new modules, fixing what’s clunky, or finally connecting it to the rest of your tools.

We don’t jump to rebuilds. First, we run a focused discovery phase: digging into what works, what breaks, and where the gaps are. That includes workflows, integrations, performance, and UX issues, whatever’s slowing you down.

From there, we map a practical path forward. That could mean:

Adding new modules without overhauling the whole system

Rewriting brittle logic (like order handling or replenishment)

Connecting external tools: TMS, WMS, customs platforms

Or planning a phased rebuild if the foundation just can’t keep up

We’re not here to sell a shiny replacement. We’re here to make sure your ERP helps your supply chain move, not hold it back.

Supply chain operations are complex, and when tools don’t fit, the whole system can turn chaotic.

Whether you're just starting to build a system or trying to modernize the one you already have, the goal is the same: full visibility, fewer delays, and smoother coordination across your entire network.

At Clockwise Software, we've spent over a decade building custom systems that do exactly that: ERPs that connect logistics, procurement, production, and finance into one coherent platform. We've seen what works, what breaks under pressure, and what it takes to build something that lasts and keeps delivering value as your business grows.

If that sounds like the ERP you’ve been trying to build, we’re ready to help you do it right.