AI solutions

What we do

Services

Experts in

How we work

Logistics businesses move fast — and they can’t afford delays, data gaps, or disconnected systems. Yet most off-the-shelf ERPs weren’t built for real logistics — with live fleet tracking, multi-warehouse coordination, and time-sensitive deliveries.

At Clockwise Software, we’ve been solving problems like these since 2014. Out of 200+ software projects our ERP software development company delivered, about half were custom-built business systems (including ERP platforms) or specialized modules integrated into existing software. Many of those were developed for logistics companies — including 3PL providers, last-mile delivery startups, and large-scale supply chain operations.

We wrote this article with input from our business analyst and solution architect — both with years of experience building ERP systems that power logistics operations behind the scenes. Together, we outline what to expect from a custom ERP, what pitfalls to watch out for, and what it takes to develop a system that aligns with how your teams actually operate.

If you’ve tried a generic ERP, you’ve probably seen its limits first-hand. While it handles accounting or inventory, it frequently can’t support real-time fleet tracking, last-mile coordination, or complex route planning.

Here’s why logistics needs a different kind of system.

In logistics, everything moves fast and nothing stands still. You’re juggling fleet schedules, warehouses, delivery windows, and cross-border partners—often all at once and always in real time.

That’s why logistics ERP software is built differently. It connects dispatchers, drivers, warehouse teams, and customers in one live ecosystem—keeping every moving part in sync as things change.

While a standard ERP might handle your accounting or inventory, it can’t keep up with the demands of live logistics. You need a system that’s designed for your industry—not just the back office.

Routes shift, delays pop up, and customer needs change fast. You need real-time data from GPS trackers, driver apps, and warehouse systems to stay ahead. A logistics ERP is built to sync all this information instantly, so you can make quick, informed decisions and prevent small issues from turning into missed deliveries.

Most standard ERPs, however, are designed for predictable, batch-based processes like payroll or scheduled inventory checks. They simply can’t keep pace with the dynamic, real-time demands of logistics.

Managing costs in logistics means tracking every variable: distance, load weight, delivery windows, driver hours, subcontractor fees, and more. An ERP software for logistics industry captures all these details in real time—calculating the true cost per route, shipment, or delivery attempt, including tolls, idle time, and failed drops. This granular approach lets you identify where money’s leaking and fine-tune your pricing to protect your margins.

Generic ERPs typically rely on static cost centers, which might work for stable operations, but aren’t flexible enough to handle the ever-changing nature of logistics expenses.

In logistics, a simple dashboard isn’t enough — you need to see what’s happening on the ground, right now. That means live updates on your vehicles, what’s in transit, ETAs, and anything that might cause a delay.

With a logistics ERP system, you get that real-time view across your whole network, so you can jump in fast, reroute as needed, and keep your customers in the loop — no more waiting on outdated reports.

Sure, plenty of modern ERPs offer real-time dashboards these days, but they usually focus on finance or basic KPIs. Logistics ERP takes it further. You get live updates on every delivery, every route, and every issue that matters to your day-to-day operations.

In logistics, you can’t just plug in any ERP and expect it to handle all your moving parts. Sure, most ERPs these days offer plenty of integrations—with CRM, HR, accounting, and sometimes even inventory or supply chain modules. But when you’re dealing with real-time carrier tracking, TMS, WMS, or customs systems, things get a lot trickier.

That’s where logistics ERP steps up. It’s built from the ground up to connect with specialized tools—like transportation management, advanced warehouse systems, and live GPS tracking—without endless workarounds or extra middleware. You get smoother data flow, fewer headaches, and a system that actually keeps up with your daily operations.

We approach custom software development in three clear stages:

We start by understanding exactly how your team works, then turn those real-world details into a system that keeps everything (and everyone) moving together.

This stage goes far beyond idea discovery. We map your workflows, create requirements for every feature, identify risks, design the full system architecture, including integrations with tools like TMS, WMS, and GPS, and document everything needed to guide development without guesswork.

We don’t start with features. We start by learning how your logistics business actually runs — day to day, across your whole chain. Our team also maps out where delays happen, which tasks still rely on manual effort, and how data flows (or doesn’t) between systems, people, and departments.

We also look at how decisions are made — whether it’s rerouting on the fly, managing inbound loads across multiple warehouses, or handling returns. This work helps us design a system that fits your reality — and avoids rework down the line.

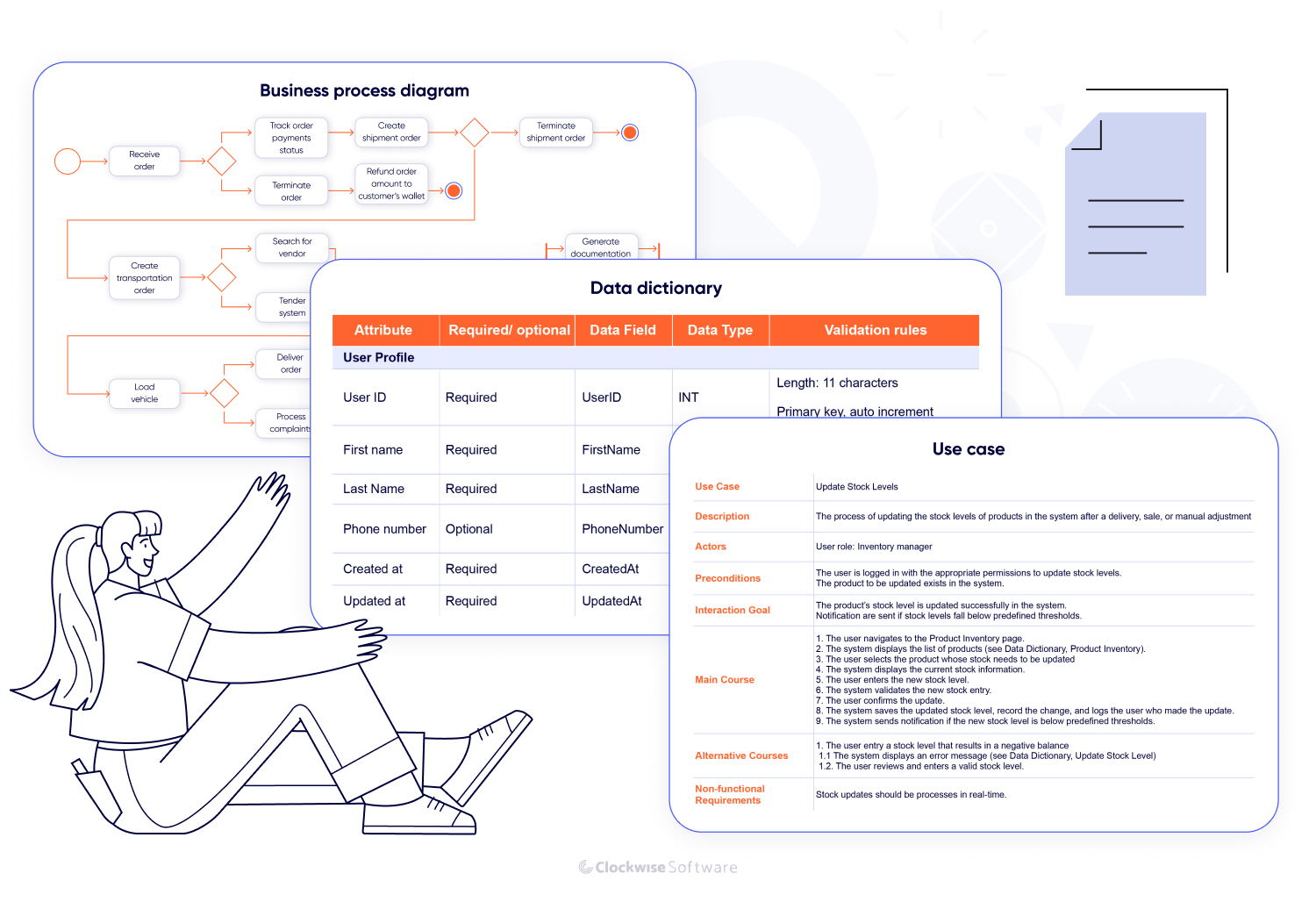

We turn real workflows into clear system requirements: how dispatch should run, how delivery statuses update, what inventory data is needed across warehouses, how driver schedules sync with orders, and how tools like GPS trackers or customs APIs need to connect. Then, we structure this into documentation everyone can follow:

Process diagrams mapping out key operations, like order flows, warehouse routines, dispatch coordination, and more

User stories or use cases capturing how dispatchers, drivers, warehouse teams, and ops managers interact with the system

Data requirements outlining what data the system collects, how it flows, and any validation or compliance rules

Wireframes for all key dashboards and screens, so you can see and test the user experience before development starts

This phase turns your daily operations into a detailed blueprint — so what gets built matches how your teams actually work.

With live tracking, complex integrations, and distributed teams, skipping risk analysis can lead to delays, scope creep, or systems that break under pressure. That’s why we assess potential issues during discovery. What we focus on:

By addressing these risks upfront, we create an ERP software for logistics industry that performs reliably under real conditions — not just in theory.

Your teams operate in warehouses, on the road, and in the field — so the logistics ERP interface must be fast, intuitive, and reliable, letting your team quickly find what they need and get work done smoothly, whether they’re in the warehouse, on the road, or at the office.

We design the interface around how your teams actually work. Dispatchers need quick access to rescheduling and tracking. Warehouse staff need mobile-friendly tools for scanning and updates. Drivers need maps, task lists, confirmations, and offline access.

Before development begins, we build a clickable prototype. Your team tests real workflows, flags friction points, and we make improvements to UI/UX design while it’s still easy to change.

We make sure your logistics ERP is fast, reliable, and easy to scale as your business grows. Here’s the stack we use to build solutions that fit these needs.

On the frontend, we use frameworks like React or Vue.js to build the entire interface—everything from fast, responsive dashboards to mobile-ready tools for dispatchers, drivers, and warehouse teams.

On the backend, we typically choose Node.js (Express or NestJS) or Laravel — depending on complexity and integration needs. These technologies support dynamic routing logic, real-time updates, and seamless communication with GPS trackers, barcode scanners, and vehicle sensors.

For databases, we rely on PostgreSQL or MySQL for structured data like shipments and delivery records, and MongoDB when more flexible storage is needed — for example, with logs or sensor metadata.

Because integrations are critical in logistics, we design the system to connect deeply with TMS, WMS, CRMs, customs APIs, and on-site hardware like RFID scanners or mobile devices — keeping data flowing across your entire network.

As for system architecture, we use modular or service-oriented architecture (SOA) to break the logistics ERP into manageable components — so it’s easy to scale, extend, or adjust without touching the whole system. If your project calls for it, we can build a monolith too — but most of the time, modular wins out for flexibility and simpler maintenance down the road.

Cloud-based ERP software infrastructure is usually on AWS, Azure, or Google Cloud. To keep your infrastructure consistent and easy to manage, we use Infrastructure as Code (IaC) tools like Terraform. This lets us automate setup, version and replicate environments, and make ongoing updates or maintenance much simpler. Background tasks, like auto-scheduling or sync jobs, are handled with serverless tools such as AWS Lambda or Azure Functions.

Once the documentation is locked in (system requirements, architecture, integration plans, and UI/UX designs) you’ve got a clear roadmap and everyone’s aligned.

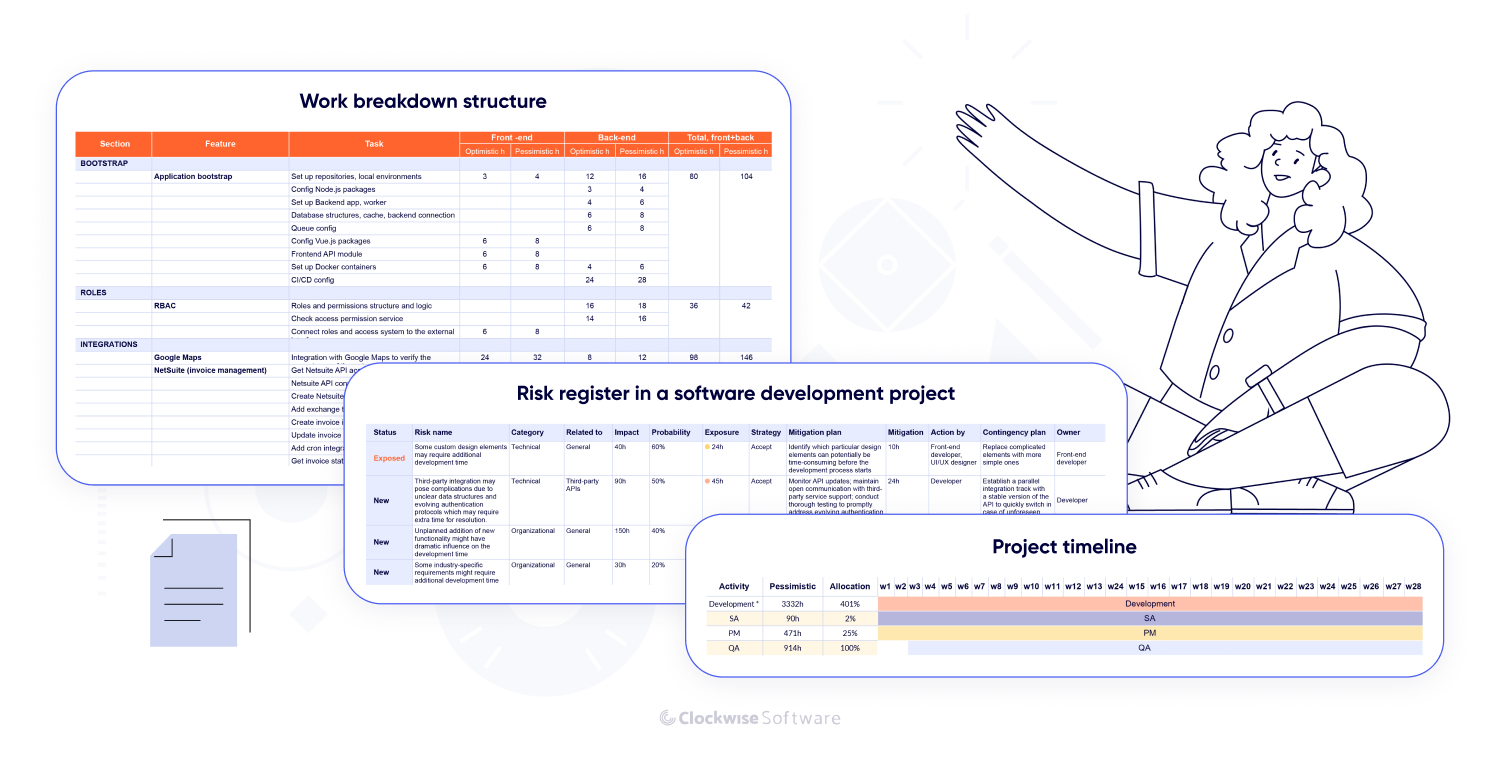

We prepare a set of docs to keep everything structured and predictable:

Detailed work breakdown structure (WBS). A clear breakdown of every feature and task, so nothing slips through the cracks.

Phased roadmap. Step-by-step plan showing what gets built when, so you always know what’s coming next.

Time and cost estimates. Honest numbers up front, helping you plan your budget and timeline with confidence.

Risk register. A heads-up list of potential issues, so we can spot and handle challenges before they turn into problems.

Based on your priorities, we tailor the team — whether you need a lean crew for MVP delivery or a full squad for parallel feature builds.

The plan stays flexible. Logistics ERP software development is rarely a straight line. Maybe you’ll need WMS integration sooner than planned. Maybe a partner throws in new requirements mid-way. We plan for changes like that from the start, but here’s the thing: logistics ERP is a big, complex system. It’s not something you can build with a fixed budget and expect zero adjustments. We’ll do everything we can to keep scope in check and avoid surprises — but to build a system that really works for your business, both sides need to stay flexible.

Project discovery phase for a logistics ERP system usually takes 4 to 10 weeks — depending on how complex your operations are. A last-mile startup with one hub moves faster than a 3PL managing customs, subcontractors, and regional fleets.

Discovery typically costs $12,000 to $25,000, depending on the number of workflows, integration points, and features involved.

This investment helps you avoid unexpected costs, sets a clear direction from the start, and gives you a solid roadmap — whether you build with us or we hand the project off to your internal dev team.

With discovery complete and the roadmap in place, we move into full-cycle development — where everything we’ve planned gets built, tested, and prepared for launch.

We start by bootstrapping the project: setting up cloud infrastructure, development environments, CI/CD pipelines, and basic security controls. This foundation keeps everything stable and consistent as development picks up speed. From there, we move through core steps:

Frontend development brings approved designs to life — creating responsive interfaces for dispatchers, drivers, and warehouse staff, with real-time updates and full support for mobile and desktop.

Backend development handles the heavy lifting behind the scenes: order processing, warehouse sync, delivery routing, and integrations with tools like GPS trackers, customs platforms, or carrier systems. We build each module to scale and keep up with live operations.

Testing happens continuously — from unit tests to real-world scenarios like missed scans or delayed deliveries. Toward the end, we shift into stabilization mode: smoothing out edge cases, fine-tuning performance, and making sure the whole system runs like it should before go-live.

User acceptance testing (UAT) puts the system in your team’s hands. You test workflows — tracking shipments, reassigning drivers, adjusting stock — and if you spot some issues, we refine functionality based on what feels natural to use day to day for your team.

Deployment happens once everything planned is ready and stable. We prepare your production environment, configure live integrations, and make sure everything’s ready for real use. Whether it’s one site or your whole network, we plan the rollout to avoid surprises and downtime. And our team stays close during the transition to catch issues early, support your users, and make sure everything runs smoothly from the start.

We work in short, 2- or 4-week sprints and deliver working results regularly, so you're never in the dark. And if priorities shift — say you need the warehouse module before fleet tracking — we adjust without derailing the timeline.

That’s the process. Now let’s look at what actually gets built.

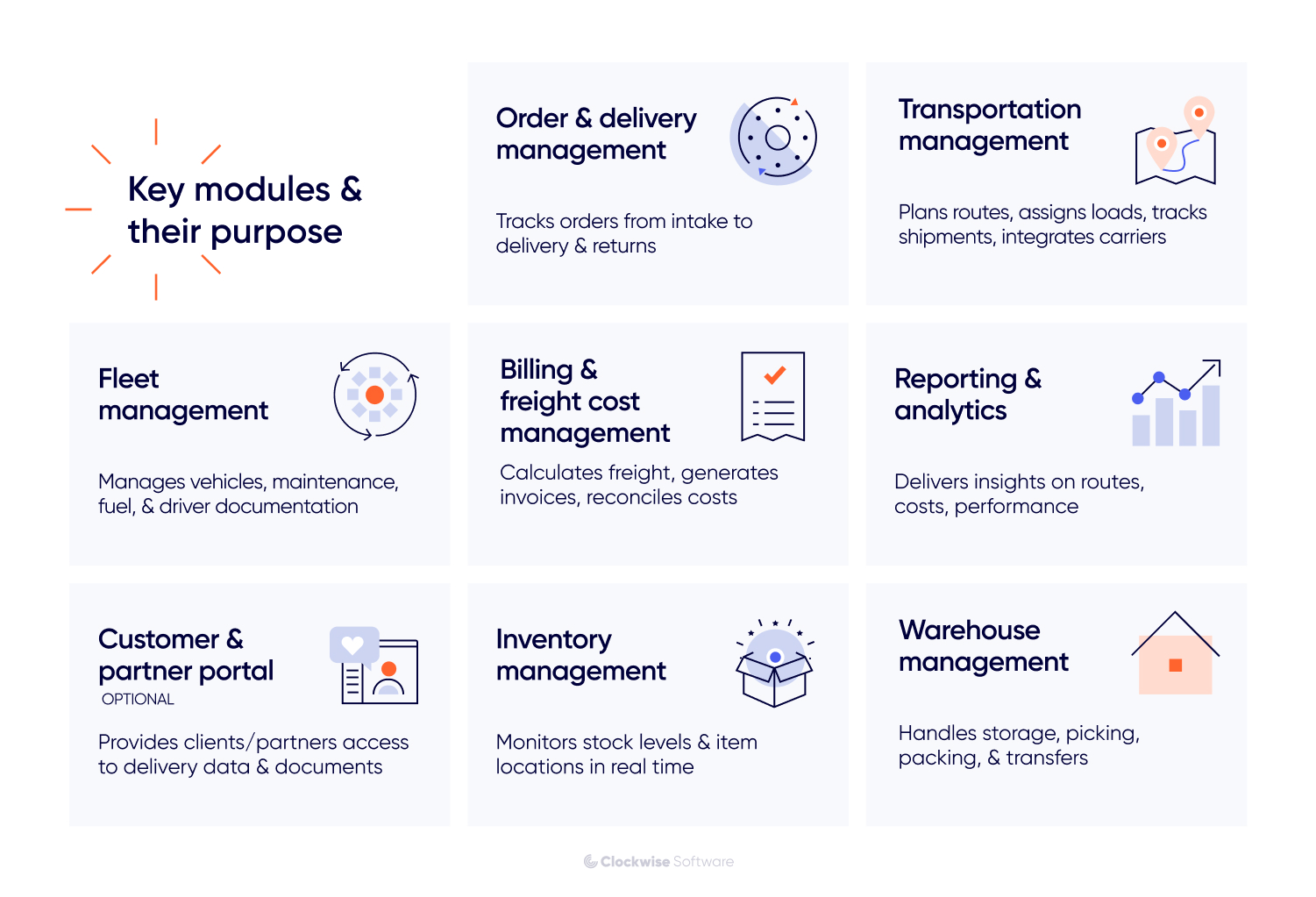

A logistics ERP software doesn’t need every feature — it needs the right ones. The tools that matter most are the ones that help you move goods faster, avoid delays, and keep operations running smoothly across warehouses, fleets, and delivery networks.

From our experience across 10+ logistics software development projects, here is the most valuable ERP functionality that improves visibility, coordination, and control — connecting every part of the delivery chain in real time.

In logistics, one missed handoff can throw off the entire delivery chain. The order management system development will allow to keep everything on track: from order intake to final delivery (and even returns, if needed).

If you’re a retailer or manufacturer with in-house logistics, it also syncs your inventory across warehouses and shipments, so nothing gets lost or duplicated along the way. But if you’re a logistics company focused only on handling and delivering orders for others, this inventory sync isn’t always required.

We’ve used similar logic in multi-supplier platforms like Strapping, where automated coordination and pricing validation reduced errors across high-volume order flows. In logistics, this same structure keeps fulfillment reliable — no matter how many partners, products, or locations are involved.

Transportation is the backbone of logistics. This module handles load assignments, route planning, shipment tracking, and integrates with your fleet or third-party carriers, so you always know where every delivery stands.

The system factors in volume, time windows, and priority levels. You can define assignment rules, monitor performance, and manage contracts in one place. For core transportation logic — like load assignments, route planning, and delivery tracking — we can integrate your ERP with a TMS that fits your needs. Whether you’re already using one or need help picking the right tool, we’ll make sure it connects cleanly with the rest of your system.

We’ve implemented similar functionality in the UDK project using Google Maps and Azure Maps — enabling dynamic route adjustments based on traffic, road conditions, and fuel consumption. This helped reduce delays and optimize cost per delivery.

If you manage your own vehicles, keeping them reliable, compliant, and cost-efficient is critical. This logistics ERP system module tracks your internal fleet — covering everything from maintenance schedules and certification records to fuel usage and driver documentation.

It’s not a routing tool — that’s handled in the transportation module or TMS — but it connects to those systems to make sure only ready, available vehicles are dispatched.

By logging maintenance, monitoring fuel consumption, and analyzing utilization, this module helps reduce breakdowns, cut operating costs, and improve decision-making for dispatchers.

What looks like a simple invoice often hides dozens of factors — from distance and load weight to fuel surcharges and failed drops. This module handles everything from freight rate calculations to accessorial charges, helping you stay both profitable and accurate.

It captures cost drivers like weight, distance, time sensitivity, fuel surcharges, and special equipment — ensuring every invoice reflects the actual service delivered. You can also reconcile third-party carrier bills, flag discrepancies, and sync billing data with your accounting tools, whether that’s QuickBooks, NetSuite, or even a custom system.

By keeping billing aligned with operations, this module reduces errors, speeds up payment cycles, and gives you a clear view of true logistics costs — shipment by shipment.

Knowing where your trucks are is useful — but it won’t tell you why orders are late or where bottlenecks happen. This module delivers the insights your team needs to make faster, better decisions, from the warehouse floor to the C-suite.

It tracks KPIs like delivery times, cost per shipment, and fleet utilization. You get real-time dashboards, clear reporting on route and carrier performance, and the ability to filter by region, customer, or shipment type. Exportable reports make sharing with internal teams or partners easy.

Advanced analytics like demand forecasting or predictive routing can be added later — but we start with the essentials that help you take control today.

As logistics operations scale, manual communication with clients and partners quickly becomes a bottleneck. A secure, self-service portal solves that—giving customers, carriers, or subcontractors direct access to only the data, documents, and delivery statuses they’re allowed to see. With role-based access, each external user gets a tailored view, so sensitive information stays protected and your internal team isn’t bogged down with manual updates.

While this module usually comes after the MVP, it’s one of the most common follow-up requests — especially for companies working with multiple clients or external carriers. Adding a portal improves transparency, reduces support workload, and strengthens long-term relationships across your logistics network.

If you’re in retail or manufacturing and handle logistics in-house, inventory management is a must-have for your ERP. This module gives your team real-time visibility into stock levels and item locations, helping you avoid delays, stockouts, and costly mistakes. It supports multi-location tracking, fast transfers, barcode scanning, and direct integration with WMS. Your teams always know what’s available, where it is, and what needs restocking.

We’ve seen firsthand how effective inventory management software development can transform operations. In the UDK WebOffice project, for example, real-time inventory sync eliminated fulfillment delays and improved load planning. The same approach applies here — keeping your inventory accurate, your teams aligned, and your deliveries on schedule.

This module also plays a huge role in ERP for food industry, helping manage perishable goods margins and avoid spoilage-related losses.

This module is essential if you run your own warehouse. Think 3PLs or logistics providers offering storage and fulfillment as part of their service, or retail and manufacturing companies managing in-house logistics. It covers core tasks like inventory tracking, bin locations, picking, packing, and internal transfers, keeping everything connected within the ERP.

For companies that only handle transportation — no storage, no fulfillment — warehouse management isn’t usually a priority. In those cases, the ERP can skip this module or connect with whatever external system your clients already use. But if you need end-to-end control, a built-in or integrated WMS makes life a lot easier for your ops and warehouse teams.

You’ve seen what the system needs to do — now here’s what it takes to make it happen.

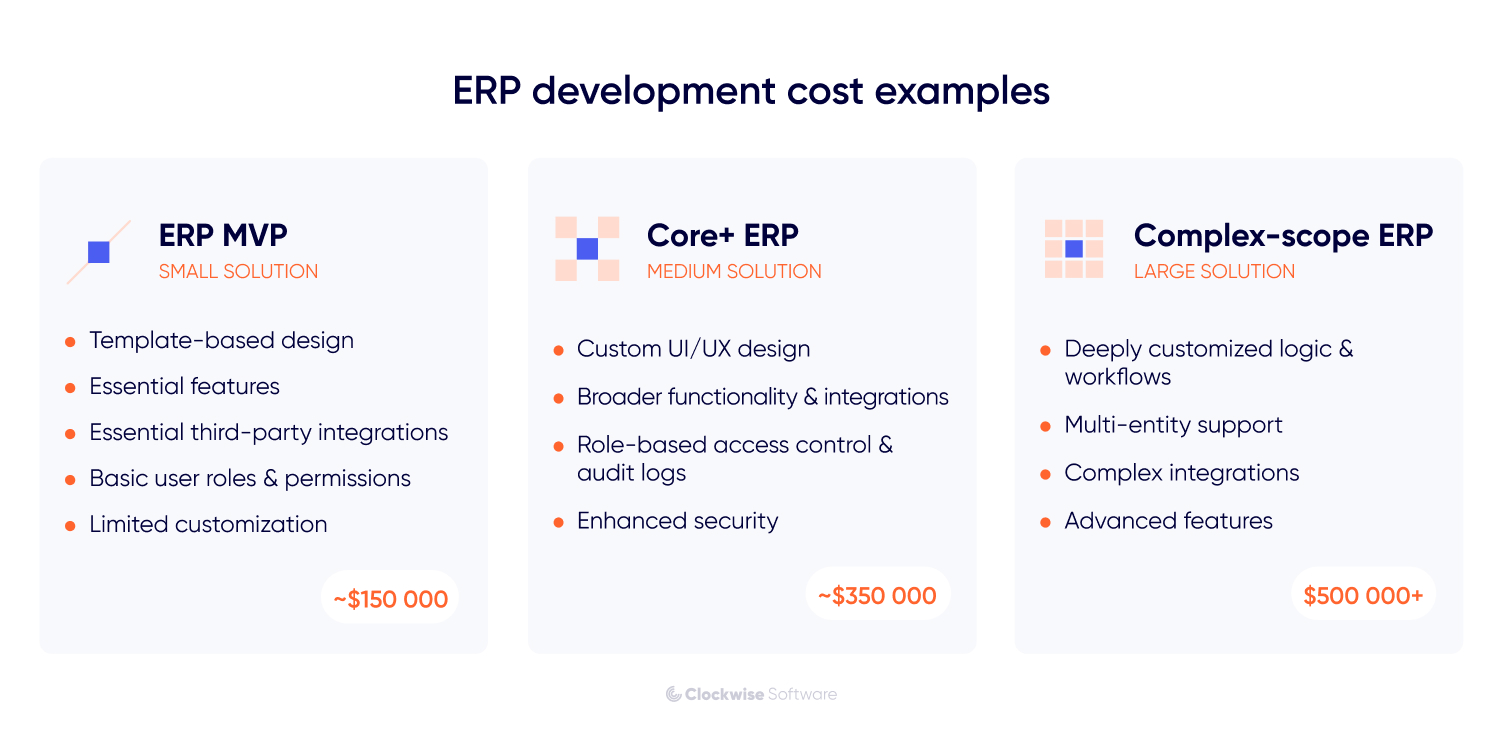

The time and costs to develop a software product depend heavily on what you need — how many modules you’re planning, which third-party tools must be integrated, and how complex your workflows are.

If you're starting with an MVP, you can expect around 6 months of development and a budget between $150,000 and $200,000. This usually includes core features like order management, delivery tracking, WMS/TMS integration, and basic reporting — enough to launch the system and start using it in real operations.

For a full-scale ERP — one that includes fleet and subcontractor management, billing automation, and advanced analytics — the timeline typically extends to 9–12+ months, with a budget in the range of $350,000 to $500,000+.

To make it easier, we’ve pulled together three examples of ERP builds different by size and complexity: from a lean MVP to a mid-size system and a full-scale platform, so you can get a sense of what fits your goals.

If needed, you can start with an MVP, validate it in the field, and then scale as your logistics workflows evolve.

A successful launch sets the stage for what matters most: long-term improvement and adaptability. As your delivery network grows, warehouse activity ramps up, or new partners come onboard, the system needs to evolve with you.

We offer flexible post-launch support — from a small maintenance crew to a full dedicated development team.

| Team composition | Monthly budget |

|

$12,000 |

|

$48,000 |

| * On-demand involvement | |

Over time, many clients evolve their systems by:

Expanding warehouse and fleet modules as operations scale

Adding new carrier or WMS integrations

Updating dashboards and reports as your KPIs evolve, so your team always sees what matters most

Introducing workflows for returns, customs clearance, or partner access

Optimizing performance as data volumes increase

Our team stays engaged, monitoring performance, resolving issues, and implementing improvements — without disrupting daily operations.

Many companies outgrow their systems — or find out that their ERP was never built for real-time delivery coordination, complex routing, or integrating with third-party carriers.

We often step in to modernize existing platforms — whether that means updating an old custom build, untangling plugin-heavy systems, or helping you move away from an off-the-shelf ERP that no longer fits. Our focus is always on making what you have work better, not starting from scratch unless absolutely necessary.

That might mean tuning performance to speed up processing and syncing, expanding features like subcontractor tracking or load assignment, or improving UX for dispatchers and warehouse staff. In other cases, we integrate new tools — from TMS and WMS platforms to 3PL carrier APIs or customer portals. And when it’s time, we help replatform legacy systems onto modern, scalable architecture — with minimum distractions for your daily operations.

We start with a focused discovery phase to assess what’s working, what’s not, and where the gaps are. From there, we build a practical upgrade plan that strengthens your ERP without hitting pause on your business. The goal isn’t to replace everything — it’s to get your system back in sync with how your logistics operation really runs.

General ERPs weren’t built for logistics. They don’t manage live shipments, dynamic routes, multi-warehouse inventory, or carrier coordination the way your teams actually need.

A custom ERP gives you control over every step of your logistics chain — designed around your workflows and long-term goals.

At Clockwise Software, we’ve provided logistics software development services for companies to replace fragmented tools, streamline operations, and build ERP systems that scale — without slowing down when volume spikes or routes change.

If you’re ready to move past generic solutions and build a logistics ERP system that fits your business, we’re here to help. Whether you need an MVP or a full-featured platform, let’s build a system that makes your operations more efficient.