AI solutions

What we do

Services

Experts in

How we work

Building an ERP for the food and beverage industry means covering a lot: inventory, compliance, production, distribution, and everything in between. The challenge is keeping it efficient, scalable, and functional without letting it spiral into a bloated mess.

As an ERP software development company with 10+ years of experience creating business systems, including ones for the food and beverage industry, we know what decisions work for each case, so you get a great product. We’re covering them all today.

We’ll walk you through the entire development process, highlight the features that actually make an impact, break down costs, and cover the tech approach we go with on ERP projects.

But first, let us explain the power of a food and beverage ERP over a general-purpose one.

Running a food and beverage business means juggling perishable inventory, strict regulations, unpredictable demand, and margins that leave little room for error. To stay on top of it all, you need smooth workflows: real-time stock tracking, compliance checks, and smart production planning.

A general-purpose ERP can cover the basics, but when it comes to the details that actually keep an F&B business operating efficiently, it falls short. Here’s where an ERP for food and beverage industry makes the difference:

An F&B ERP lets you keep track of shelf life, automates FIFO/FEFO stock rotation, and warns you when ingredients are about to expire so you can use them before they become a loss. A general-purpose ERP rarely provides this functionality; it logs inventory but doesn’t factor in expiration dates.

Food safety laws require full traceability, and if there’s ever a recall, you need to act fast. A general ERP might store product and supplier info, but it won’t help much when regulators come knocking.

An F&B ERP can track batches from supplier to sale, generate HACCP reports automatically, and let you pinpoint affected products instantly if a recall happens.

Production in F&B is about managing recipes by balancing ingredient costs, portioning, and unpredictable yield changes. General ERPs use standard bills of materials, but they don’t account for changing ingredient prices or batch variations. With a food and beverage ERP, you have the functionality to track real-time costs and adjust portion sizes dynamically, so you can price products profitably even when your costs shift.

Predicting demand in F&B is tricky: one week, something’s flying off the shelves; the next, it’s barely moving. A general ERP might give you historical sales data, but it won’t help much with forecasting. An ERP for food and beverage industry looks at past trends, seasonality, and external factors to predict demand so you’re not stuck with too much stock or, worse, running out when customers need it.

An ERP for food and beverage industry gives you real-time profitability insights, showing where you can cut costs, adjust pricing, and improve efficiency before small losses turn into big problems. A general-purpose ERP, in turn, usually provides standard financial reports that don’t break down profit margins by product, batch, or ingredient.

So, a general ERP might cover basic needs in inventory and sales, but a food and beverage ERP is built to help you run your business more effectively: cut waste, improve compliance, and keep your bottom line in check.

Now, let’s talk about how to build an ERP, starting with an overview of the development stages.

Developing a food and beverage ERP follows the same core process as real estate ERP software or any other one. But with industry-specific challenges and needs in mind. The 3 key stages look the following way:

That’s the high-level overview, but each stage has its own details that separate a reliable ERP from one that causes more problems than it solves. Let’s start with project discovery.

When building a complex system like an ERP, a solid discovery stage can mean the difference between a well-planned project and one that burns through time and budget. This stage is where you define every detail of your system and plan how to build it so development stays predictable, without mid-project redos that add months to the development timeline and $30k+ to the project budget.

Here’s what we do during discovery to prepare for development in the best possible way:

Before building anything, we need to get a clear picture of how your operations actually work. That means looking beyond surface-level needs and mapping out the daily workflows, pain points, and dependencies that drive your business. For this, we set up calls with you and ask questions like:

These questions help us map out what your ERP needs to fit your business today and support where you want to go next. After all, an ERP that doesn’t adapt to your operations and optimize them is just an expensive database. We avoid it by understanding your workflow, needs, and goals at the start.

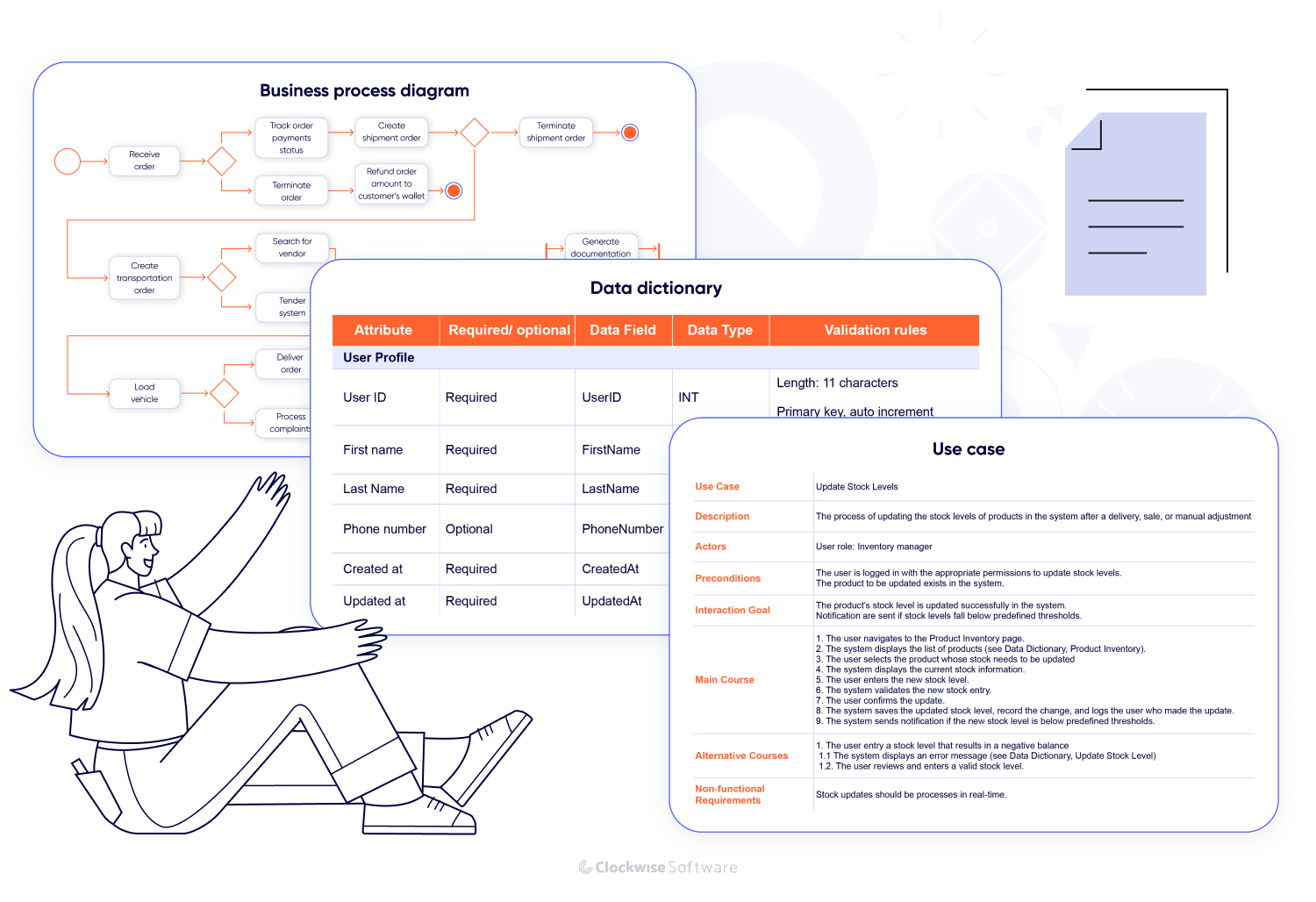

Once we understand how your business runs, the next step is turning that knowledge into a structured plan. We map out workflows, define features, outline how information moves through your ERP, and more to have a full picture of what your ERP will do, how it will function, and how all parts are connected.

All this will be documented in various formats, including:

We’ll walk you through it all, explaining our approach and answering your questions. If something doesn’t feel right, we’ll adjust it to meet your vision. The goal is to structure a system that actually makes sense for your business.

The last thing we want (we’re sure you too) is to meet major issues halfway through the project or understand that our plan is not technically feasible. So, we explore potential software development risks during project discovery.

One key area we examine is integration with existing tools. Whether it's inventory management systems, supplier portals, accounting software, or IoT sensors for temperature control, each has its own specifics. Our software architect reviews documentation and tests connections to identify potential risks and define the strategy for connecting systems.

We also look at data migration challenges: if you have years of purchase records, supplier contracts, or recipe formulations, we figure out how to move that data without breaking anything.

For anything high-risk, we build a proof of concept — a small test run to validate API connections, check system compatibility, and compare different service options. This extra step helps us avoid surprises, reduce rework, and keep development on schedule.

We take the wireframes from the previous step and refine them into a design that lets your team navigate the system without endless clicks and confusion.

We also create an interactive prototype so you can click through screens, test navigation, and see exactly how the system will feel before development even starts. We’ll walk you through everything and adjust the details based on feedback.

It’s time to choose the technologies for building your ERP and design its architecture in detail. Here are the technical decisions we usually make and the solutions we find optimal for ERP development:

For web-based food and beverage ERP software, JavaScript is our go-to — it’s flexible and widely supported. On the frontend, we work with React, Angular, or Vue.js to build an intuitive, fast, and enjoyable interface (because nobody wants to wrestle with a clunky system).

The backend is where the heavy lifting happens, and we typically use Nest.js or Express.js to process business logic, handle integrations, and everything else behind the scenes. If PHP is a better fit for your project, Laravel is a strong alternative for creating a scalable backend that won’t slow down as your business grows.

We usually go with a service-oriented architectural approach: instead of cramming everything into one massive, hard-to-maintain system, we break it down into separate, focused services. Think of it like this: your inventory management, order processing, and compliance tracking each work as its own components, meaning we can change one without messing with the entire system.

And if real-time data tracking is on your radar, like monitoring temperature-sensitive ingredients or tracking production in real time, we’ll use event-driven architecture to process live updates without delays.

For cloud-based ERP systems, we rely on AWS, Azure, or Google Cloud. These platforms provide a robust set of tools to streamline ERP development, deployment, and scaling. For example, when choosing AWS, we use tools like Elastic Beanstalk for automatic scaling and AWS Lambda for serverless computing to optimize resource usage and reduce overhead costs.

To keep infrastructure consistent and manageable, we implement Infrastructure as Code (IaC) with Terraform or AWS CloudFormation, allowing for version-controlled deployments, seamless environment replication, and easier long-term maintenance.

With data encryption, role-based access control (RBAC), and automated backups, we make sure your business-critical data is safe from breaches or accidental loss. And if compliance is a concern (which, in F&B, it always is), we’ll discuss it with you and define additional measures to implement in your ERP.

All in all, our solution architect will choose the right tech approach for your ERP and walk you through our decisions, making sure the system is built to fit your needs, scale with your business, and integrate smoothly.

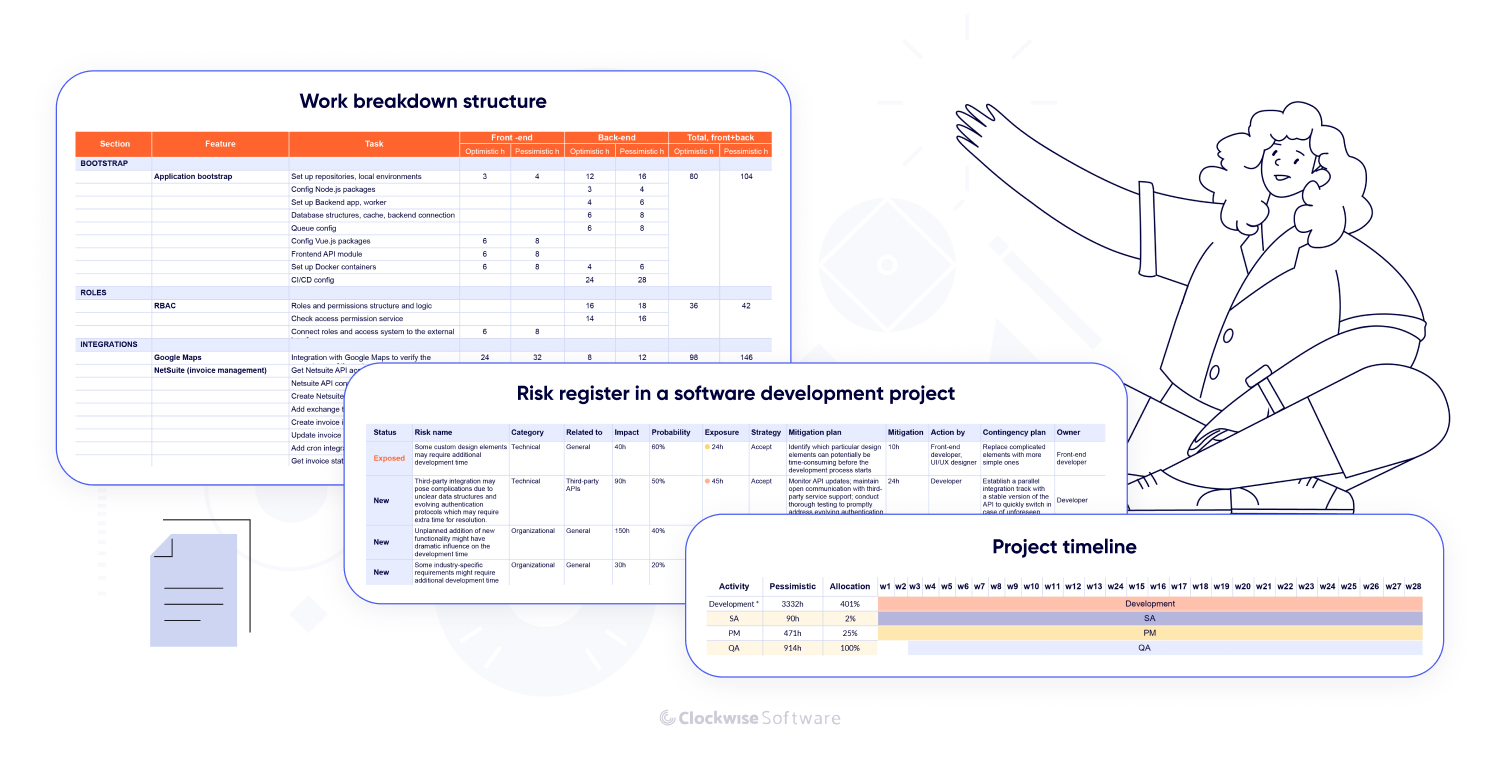

With all the system details mapped out, it’s time to refine the documentation and set up a clear development plan. Here’s what you’ll get at this step:

So, by the end of the discovery stage, you’ll have a structured plan, estimates, and a roadmap to build the ERP you want.

But there’s one thing to keep in mind:

ERP projects rarely fit into a fixed budget.

These systems are complex and take 9+ months (sometimes years) to develop, so changes will happen. New priorities might emerge and require changes to the project scope, or unexpected challenges can pop up. That’s why we provide both realistic and pessimistic estimates upfront and keep you in the loop at every stage. Planning is crucial, but so is staying flexible — on both sides. Just as we adapt to challenges and changing priorities, your team should be prepared for changes in timeline and budget, too.

Project discovery for food and beverage ERP software typically takes 4 to 10 weeks — duration mostly depends on the complexity of the system you want, as well as of your operations. The more intricate your workflows and needs are, the more time we’ll need to properly map out functionality and requirements. The scope also affects the cost, which usually ranges from $12,000 to $25,000.

For a detailed breakdown of the time, cost, and deliverables involved in the discovery stage, check out our whitepaper.

After the discovery stage, we assemble the development team and get to work. A development process looks like this:

1. Application bootstrapping

First up, we configure the infrastructure, frontend, and backend to ensure a smooth development workflow. This includes setting up repositories, version control, development environments, and CI/CD pipelines for automated testing and deployment. With everything in place, we’re ready to move forward.

2. Frontend development

Our frontend developers turn UI/UX designs into a working interface, ensuring buttons perform the right actions, data tables allow easy filtering, and navigation follows a clear, predictable flow. We also take care of responsiveness so the system functions as expected, no matter what devices your team uses.

3. Backend development

On the backend, we build the core functionalities that process user actions, store and retrieve data, and connect with third-party tools like accounting or supply chain systems. APIs are set up to handle integrations, while performance optimization ensures the ERP runs efficiently, even when handling large volumes of transactions.

4. Testing, regression, and stabilization

Our QA engineers test features as soon as they are built, verifying that everything works as expected and meets the requirements. Any issues get reported to the developers for immediate fixes.

Once all features for the initial version are complete, we run regression testing to ensure that adding functionality together hasn’t caused unexpected issues in the system.

The next step is stabilization, where we refine and optimize the ERP before launch. This includes fixing any remaining bugs, fine-tuning performance, and ensuring smooth data handling. The goal is to deliver a system that runs reliably under real-world conditions.

5. User acceptance testing

It’s time for another test, but this time, your team gets hands-on with the ERP. You’ll navigate through the system, run everyday tasks, and see if everything works as expected. This step ensures the ERP isn’t just functional but actually fits how your business operates. Based on your feedback, we’ll make adjustments and fine-tune anything that doesn’t feel right.

6. Deployment

When everything is tested, it’s time to start your system rollout. We set up the system in the production environment, configure databases, and ensure all integrations work as expected. Before going fully live, we often run additional tests, checking performance, security, and data integrity to catch any last-minute issues. Once everything is verified, your ERP is ready for real-world use.

We break ERP development into 2–4 week iterations, each focused on building and refining specific features. This step-by-step approach keeps the process flexible, making it easier to identify issues early, adapt to changes, and avoid costly rework. Instead of waiting until the end to see how everything comes together, you’ll get to review progress regularly, confident that the system is shaping up as expected.

Now, let’s talk about the result of development: your ERP system’s functionality.

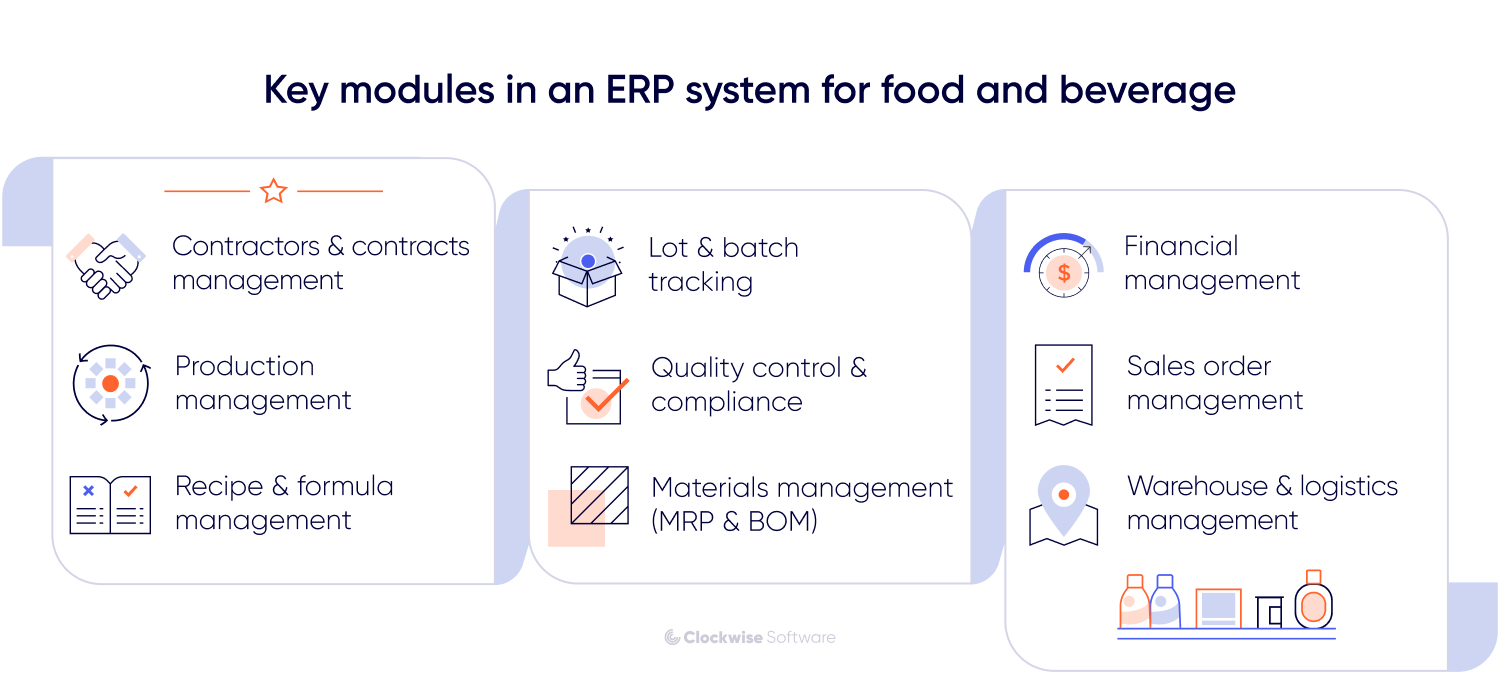

A custom ERP is built around your business: you get full control over what goes in, ensuring every module serves a real purpose. Here are examples of high-impact ERP modules based on what we’ve seen working for our clients to give you a sense of what your ERP can include.

For: Manufacturers, distributors & wholesalers

Managing contracts shouldn’t feel like a never-ending paper chase. This module keeps all your supplier, vendor, and private label agreements in check. You can view and manage roles, responsibilities, terms, pricing, deadlines, and renewals in one place.

For: Manufacturers

Keeping production on track is a balancing act: ingredients, schedules, equipment, and teams all need to work in sync. This module in ERP for manufacturing companies helps you plan and monitor every step, from raw materials to finished products. It tracks production schedules, automates work orders, and ensures you meet demand without overproducing. Plus, we connect it with inventory and batch tracking, so you never run out of key ingredients mid-shift.

For: Manufacturers, food service providers

This module standardizes recipes and formulas, ensuring consistency in taste, quality, and cost. You can track ingredients, portion sizes, and nutritional values while linking everything to inventory.

We’ve built similar tech for Nutritious Grocer, an app that helps users cook with products they have right now. In an ERP, this means smart ingredient tracking, automatic cost calculations, and ensuring compliance with food regulations.

For: Manufacturers, distributors & wholesalers

This module assigns lot and batch numbers to every product, making it easy to track items from raw materials to finished goods. Need to recall a batch? You’ll know exactly where it went. Expiry date coming up? Get alerts before products go to waste. Whether you're handling perishable goods or need full compliance with safety regulations, this module keeps your inventory under control.

For: Manufacturers, distributors & wholesalers

This module helps you track product quality at every stage, from raw materials to final packaging. Automated checks, digital logs, and real-time alerts keep you audit-ready for HACCP, FSMA, BRC, and other standards, so compliance reporting isn’t a problem.

We’ve built a similar functionality on one of our projects. We integrated a system with IoT sensors that monitor air quality and energy efficiency, helping businesses meet strict EU compliance standards. The same principle applies here: detailed tracking, instant insights, and easy reporting.

For: Manufacturers, distributors & wholesalers

This module keeps your inventory lean and efficient with BOM tracking, real-time stock visibility, and demand forecasting. FEFO ensures perishable items don’t go to waste, while automated procurement and supplier management prevent pricing errors.

We did a similar functionality for Strapping, an e-commerce business, implementing the FIFO approach to simplify and streamline calculations. Implementing FEFO in your ERP system for food and beverage will bring the same business value: we can fine-tune cost tracking so you don’t lose money on mismanaged stock.

For: Manufacturers, distributors & wholesalers, food service providers

This module tracks ingredient costs, production expenses, and tax compliance while automating billing, invoicing, and multi-currency transactions. Real-time financial reports and profitability analysis help you fine-tune pricing and keep margins healthy.

We’ve seen how smooth payment processing can be a game-changer when working on WijnSpijs, where integrating Dutch payment services made transactions seamless for customers and vendors. Whether you’re handling B2B orders or direct-to-consumer sales, this module keeps cash flowing without the headache of manual errors.

For: Distributors & wholesalers, manufacturers, food service providers

This module automates order processing, invoicing, and pricing—whether you're dealing with bulk discounts, weight-based pricing, or custom rates. EDI integration eliminates manual data entry, making supplier and distributor communication faster and error-free. Plus, real-time order tracking keeps you on top of deliveries and stock levels, so you avoid overpromising or underdelivering.

For: Distributors & wholesalers, manufacturers

This module handles stock movements, automates replenishment, and optimizes picking routes for faster fulfillment. Barcode and RFID scanning speed up receiving and dispatching, while real-time tracking ensures you always know where your products are.

The modules we’ve covered are just the beginning. Your ERP will be built around your unique operations, with exactly what you need and nothing you don’t.

Developing a custom ERP for the food and beverage industry starts at $350,000, with timelines beginning at 9 months. The exact cost and duration depend on the system’s complexity, integrations, and specific business needs.

Let’s look at an example of an ERP for a food and beverage distributor. Here is what functionality it might include with estimates based on what we’ve dealt with on our projects:

For ERP solutions with broader functionality, covering everything from inventory and production tracking to compliance and supply chain management, the cost of custom software development can exceed $500,000 and take a year or more.

We can also start with a minimum viable product (MVP). This approach focuses on including only essential features and the most critical modules in your ERP, allowing you to optimize key workflows or test the system before scaling up while also minimizing the costs of software development. Depending on scope, an ERP MVP typically costs between $150,000 and $200,000 and takes around 6 months to develop.

Releasing your food and beverage ERP system is not a finish line. Here start another stage, where we:

Basically, the cost of post-release support depends on what team we need to allocate. But a software development team structure depends on what you need and how quickly you want it done:

Here’s an example of how the budget scales based on team size:

| Team composition | Monthly budget |

|

$12,000 |

|

$48,000 |

| * On-demand involvement | |

No two F&B businesses are alike, and neither are their ERP development needs. Whether you're starting from scratch, improving an existing system, or just figuring out the best way to move forward, we’ve got flexible cooperation models to match your situation. Here’s how we can work together:

Product development service

Need a full-cycle ERP development partner? We take the reins from start to finish — planning, designing, building, and launching your custom ERP — while keeping you in the loop with regular updates and checking in on key decisions. This way, you get the desired solution without the need to closely monitor and manage development. You can stay focused on strategy, growth, and everything else that keeps your business running.

Dedicated team service

Already have an ERP but need extra hands to enhance it? Our dedicated team model lets you scale your development team with experienced engineers, designers, and QA specialists who integrate seamlessly with your existing setup. Whether it’s adding new modules, improving performance, or handling maintenance, you get the expertise without the hassle of full-time hiring.

Software development consulting

If you're in the early stages and need expert guidance, our software development consulting services help you determine the best way to digitalize your processes. From defining system architecture to selecting the right technologies and planning a development roadmap, we ensure you make informed, strategic decisions before jumping into full-scale development.

The beauty of a custom ERP is that you get exactly what you need: no useless extras, no missing essentials. But the final result depends on countless decisions made throughout development: what to include, how to structure it, and how to ensure it actually works for your business. There’s no one-size-fits-all ERP, but with the right approach and experience, you can build a system that fits your needs instead of just being an expensive database.

We’ve spent over a decade building ERPs for the food and beverage industry, so we know what makes a system work (and what turns it into a mess). Whether you're starting from scratch or fixing an existing ERP, we can help define the right features, design architecture for long-term growth, implement functionality, and integrate a system with your tools. Just drop us a line so we can schedule a call.