AI solutions

What we do

Services

Experts in

How we work

If you work in automotive, you already know: most ERP systems weren’t exactly built for your world. Multi-plant coordination, layered supply chains, strict compliance — these aren’t things you can fix with a plugin.

We’ve seen it firsthand. At Clockwise Software, we’ve built over 200 custom systems since 2014 — including ERP development solutions and core modules for manufacturing-heavy businesses, automotive among them.

This guide pulls together everything we’ve learned — with insights from our business analyst and solution architect. No filler, no lofty promises — just what actually works when you’re building ERP for automotive production environments.

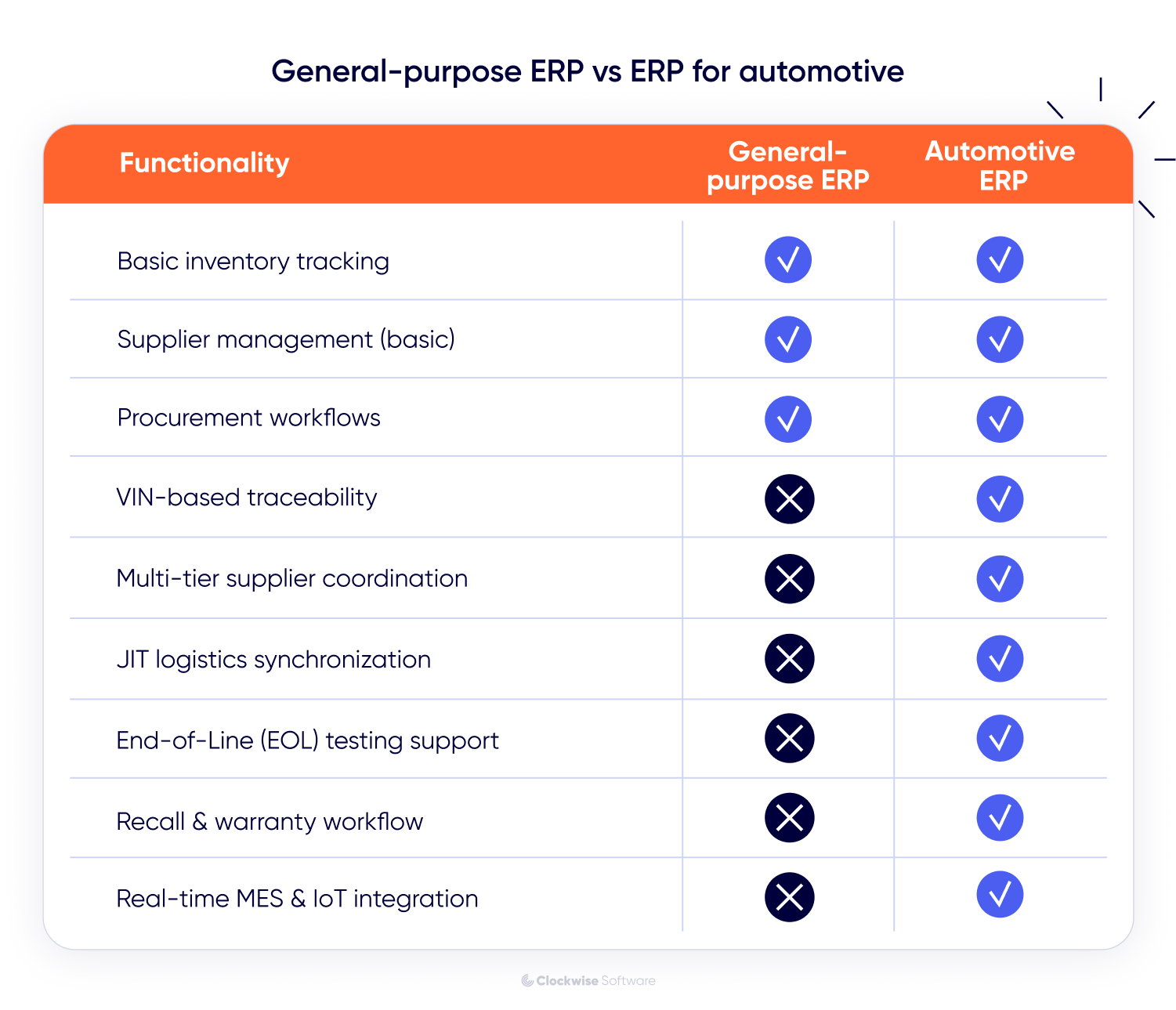

Generic ERP systems can handle a lot — accounting, inventory, HR, even basic production workflows. But in the automotive industry, “basic” doesn’t cut it.

When you're juggling multi-tier suppliers, JIT logistics, traceability, compliance, and nonstop plant floor coordination, a general-purpose ERP just isn’t built for that kind of pressure.

Here we break down where standard systems hit their limits — and how an ERP designed specifically for automotive helps you stay on schedule, in control, and audit-ready when every delay or defect has real consequences.

Basic ERPs track inventory, but in automotive, that’s just step one. Whether you’re running JIT, Make-to-Order, or a hybrid model, your ERP has to sync multi-tier suppliers and production in real time—otherwise, a single delay can stop everything. Even the best ERP for manufacturing may struggle with that.

A solid automotive ERP adapts to your workflow, giving you live inventory, supplier status, and delivery updates. No matter how you build, you stay lean, flexible, and ready to handle last-minute changes without risking downtime.

Basic procurement tools won’t get you far when your supply chain spans dozens of vendors across multiple tiers. You need full visibility and coordination with every supplier — whether they're Tier 1 or further down the chain.

Automotive ERP solutions come with EDI (Electronic Data Interchange) built in — so purchase orders, shipping updates, invoices, and quality reports flow automatically between you and your suppliers. Without it, real-time coordination across OEMs and suppliers just doesn’t happen.

EDI and supplier scorecards are built in from the start, giving you faster communication, fewer errors, and tighter control over every step of your supply chain.

Automotive regulations leave no room for gaps — and no tolerance for manual workarounds. The standards are tighter, the risks are higher, and the margin for error is almost zero.

Automotive ERP software doesn’t guarantee compliance, but it gives you the tools you need: full part traceability, automated inspection logs, lot and serial tracking, End-of-Line (EOL) testing, and structured recall workflows. That way, you’re ready for audits and can keep up with IATF 16949, ISO 26262, EPA, and NHTSA requirements, without manual paperwork or patchwork fixes.

You stay ahead of audits, catch issues early, and keep every part moving through the line with confidence.

Most general ERPs stop at records and reports. They don’t track machine status, flag early signs of equipment failure, or give you a live view of what’s happening on the line.

Automotive ERP systems do. With direct integrations to MES platforms and IoT sensors, they provide real-time production data, monitor equipment health, and track OEE(overall equipment effectiveness) as it happens — not hours later. It’s what helps you stay proactive instead of playing catch-up when something goes off schedule.

In automotive, traceability has to be precise — not partial, not pieced together.

Automotive ERP software tracks every part by serial or lot number — and once assembled, links all component history to the vehicle’s VIN. That means you can trace defects, manage recalls, and process warranty claims without digging through disconnected systems or incomplete records.

Generic ERPs often stop at batch or shipment level — which leaves traceability gaps you just can’t afford in this industry.

Not every automotive business needs this — but if you’re an OEM or distributor, it matters.

A well-built automotive ERP can plug into your dealer network to track vehicle status, manage warranty claims, handle spare parts, and sync with your CRM. It keeps post-sale operations connected to what’s happening in production — so service teams aren’t flying blind, and your customers get faster answers and fewer delays. When customers are waiting and vehicles are on the road, disconnected systems slow everything down.

That’s the real difference: with a properly built automotive ERP software, you get live supply chain control, full part traceability, and compliance handled without the daily firefighting. But none of this happens by luck or with out-of-the-box tools.

So what does it actually take to build an ERP that works for automotive?

Automotive ERP development isn’t something you rush through. It’s a full-cycle process on our side — discovery, development, and rollout — each with clear goals, deliverables, and checkpoints.

Here’s what that looks like in practice—timelines, costs, and what to expect at every step.

Jumping into ERP development without a solid discovery phase is asking for headaches down the road—missed requirements, scope creep, and nasty surprises that blow up budgets.

Discovery is where we catch all those unknowns early. By mapping your workflows, defining requirements, exploring technical constraints, and identifying issues upfront, we spot hidden risks in software engineering, uncover what actually needs fixing, and set a clear plan.

The discovery phase of a project kicks off with us sitting down with your team to get the full picture. We talk through how your processes really work day-to-day, which tools you’re already using, and where things get stuck.

Just as important, we dig into what you actually want from your automotive ERP: your goals, your must-haves, any quirks like legacy data, scaling plans, or integration needs.

The goal here isn’t to redesign your workflows. It’s to understand them well enough to build a system that supports what already works and improves what doesn’t.

With a clear picture of how your teams work, we shift focus to defining what your automotive ERP software actually needs to handle — across production, logistics, compliance, and beyond.

In automotive, that often means going well beyond standard ERP functionality. We break your automobile ERP software down into functional areas, define the features for each, and document detailed requirements, covering everything from core workflows to integrations and compliance. This way, every need is captured up front and nothing important gets missed. To keep things structured, we create:

User stories. Short, real-life scenarios that show what each user needs from the system to finish an action

Data flow diagrams. Simple maps of how info moves between modules, tools, and integrations—so nothing gets lost in translation.

Non-functional requirements. Clear expectations for speed, uptime, scalability, and security — so the system performs reliably under real conditions.

Wireframes. Clickable drafts of the main screens—so you can see the layout and flows before anyone starts coding.

This process gives us a blueprint and software development team structure, built around how your teams work, not forced to fit someone else’s template.

Each automotive ERP project comes with its technical challenges — and the earlier we surface them, the smoother development goes.

A common one is integration with legacy tools like MES, PLM, or on-premise supplier portals. Outdated tech stacks, inconsistent data formats, and limited APIs can slow things down. That’s why we review documentation and test critical connections upfront — not halfway through the build.

Data migration is another high-risk area. Part records, EDI logs, compliance data — often spread across systems or spreadsheets — need to be cleaned and moved without breaking traceability or disrupting operations.

We also assess compliance risks. Where needed, we build small proofs of concept to make sure complex modules — like EOL testing or supplier scorecards — work as expected before moving forward with full development.

For complex or high-risk areas, we often start with a proof of concept — like validating real-time data sync from MES or testing how supplier scorecards perform under actual usage. This way, we catch technical roadblocks early and plan smart ways to avoid or work around them before they cause delays.

All this work helps us keep timelines honest and avoid rework that throws off budgets or stalls the build.

Design in automotive ERP has one job: help people get things done quickly — even in high-pressure, fast-moving environments.

We take the wireframes created earlier and turn them into role-specific interfaces. Our goal is to make ERP convenient for every user so that plant managers, for example, can easily track line status in real time; quality teams — log inspections and spot defect trends without digging through spreadsheets; and maintenance crews can update equipment status right from the floor — using mobile-friendly screens built for noisy, fast-moving environments.

Since many teams (let’s be honest) have little time for learning curves, we focus on clear layouts, fast navigation, and cross-device usability.

We also create an interactive prototype, so your team can test real scenarios before development starts — and we can fine-tune anything that feels off.

Automotive ERP software has to do more than store records — it needs to coordinate production across sites, integrate with your systems, and adapt as your operation grows. That’s why we use a modern web stack, keeping your system fast, stable, and built for scale.

On the frontend, we use modern frameworks React or Vue.js for smooth, responsive UIs your team can use from rugged tablets or office desktops. On the backend, we use Node.js (NestJS or Express) or Laravel — depending on how complex your workflows and integrations are. Automotive ERPs typically connect with MES, IoT, PLM, EDI, and quality tools, but that’s just the starting point. The real flexibility comes from how the system is architected.

We use a modular, service-based architecture so every part of your automotive ERP can evolve on its own, get updates without breaking the rest, and scale up without the headaches. It makes the whole system easier to manage, adapt, and future-proof as your business grows.

We host on AWS, Azure, or Google Cloud — all solid platforms for hosting and scaling ERP systems. On AWS, for example, we use tools like Elastic Beanstalk for auto-scaling and load balancing, or AWS Lambda for serverless workloads — making the infrastructure easier to manage as you grow. With Terraform and AWS CloudFormation, your setup stays consistent and easy to manage, making updates and scaling the cloud-based ERP system hassle-free.

Bottom line? This setup keeps your infrastructure stable, secure, and easy to grow. No lag, no downtime surprises, and plenty of room to grow.

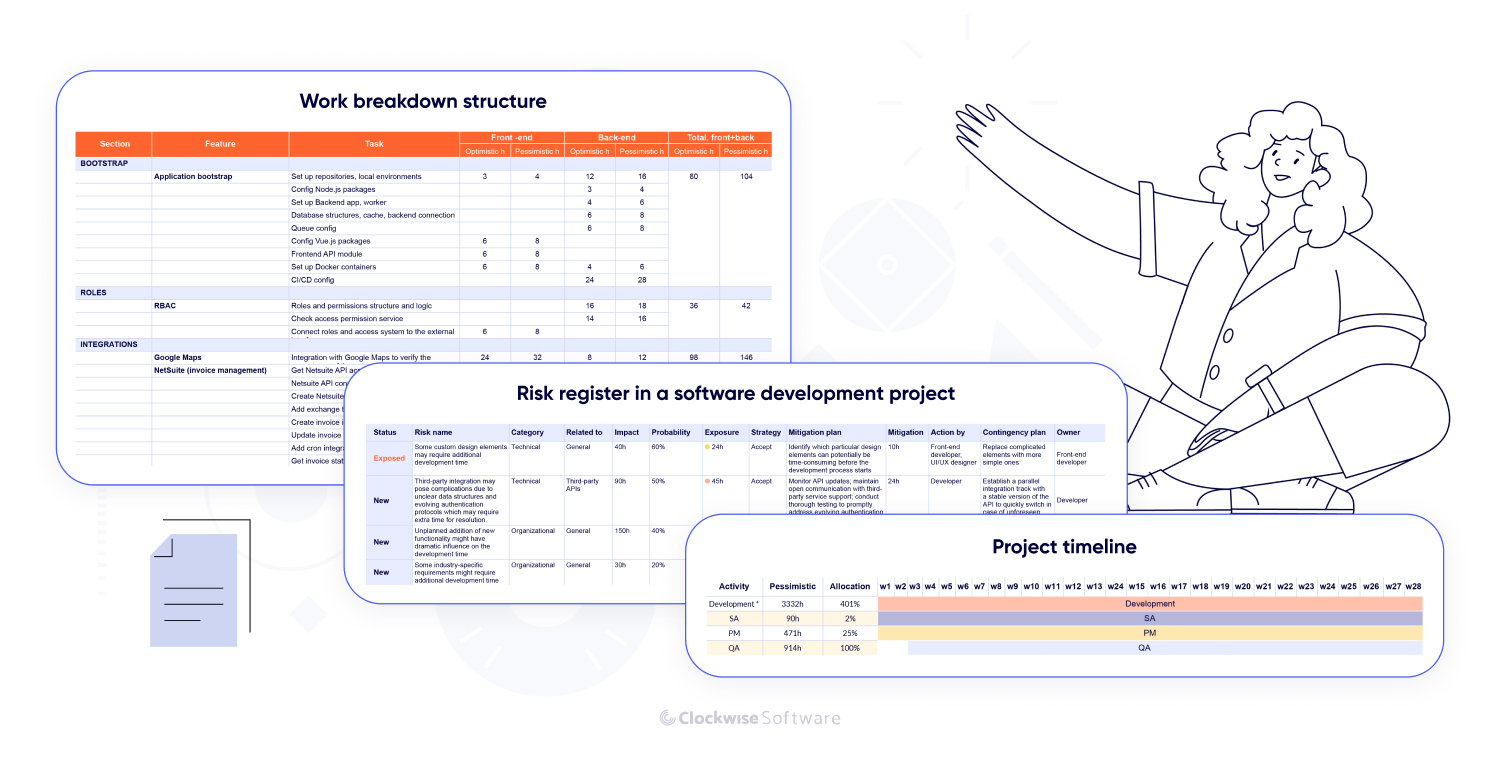

Once the tech, requirements, and designs are locked in, you’ve got a clear game plan. Everyone’s on the same page about what needs to get built and how it should work. This upfront clarity saves time, cuts down on guesswork, and helps the whole build stay on track when development starts. Here’s what we finalize before the build kicks off:

Work breakdown structure (WBS). All modules and tasks mapped out with realistic time estimates.

Cost estimate. Based on actual scope and priorities, so you know where every dollar goes.

Timeline & milestones. Clear delivery phases tied to checkpoints.

Risk register. Potential blockers (like legacy integration or messy data) and how we’ll handle them.

Team structure. Right-sized to your project, whether you're starting small or scaling big.

Before we move to the next stage of automotive ERP development, here’s one thing that we always make sure our clients know early on.

Even with a clear plan, change is almost guaranteed in a project of this scale — priorities shift, technical constraints show up, or new needs emerge mid-build. That’s why we plan for it upfront: we leave buffer time, keep estimates realistic, and stay flexible. But flexibility works both ways — your team also needs to be ready to revisit priorities or give fast feedback when things evolve. If something shifts, you’ll hear about it right away, and we’ll work with you to adjust without derailing the whole plan.

Discovery typically takes 4 to 10 weeks, depending on how complex your setup is — number of sites, systems in play, and how deep we need to go. Discovery goes quicker for a single-site parts supplier than for a Tier 1 with multiple plants, EDI flows, and strict compliance. We match the pace to your business — not overengineering it, but not skipping what matters either.

Pricing ranges from $12,000 to $25,000, depending on scope. It is a smart tactic for cost optimization in software development. Investing here means you get a clear plan upfront—so you avoid expensive rework or slowdowns later on.

With discovery wrapped, we move into full-cycle development — turning architecture, workflows, and wireframes into a working ERP for automotive industry that fits how your business runs.

We build in short sprints and give you regular demos, so you can track progress, review what’s ready, and make decisions without waiting for the full rollout.

Our team starts with the foundations: setting up cloud infrastructure, version control, CI/CD pipelines, and environments for dev, staging, and production. That way, each release is clean, traceable, and easy to deploy across teams or locations.

We start with core building blocks — login, navigation, main layouts — then move on to modules your teams rely on daily, like traceability reports or mobile-friendly floor screens. Each screen is tailored to its role, so each team member sees the info they need—fast, clear, and without extra clicks.

Your ERP’s backend handles all the business logic, data processing, and integrations — so we structure it to match. That might be a monolith for simpler setups, or a modular system if you need flexibility and room to grow.

We cover everything: secure data handling, business rules, user access, audit trails, and smooth connections to tools like MES, PLM, and EDI. You get a solid, future-proof core for your whole system.

QA kicks in right after each feature is built (not just at the end) so issues get caught early and fixes happen fast. We validate each feature as it’s built, then run full regression testing once the core system is ready. We also tune performance under load — so it works just as well on your busiest production day as it does in a demo.

Now it’s your turn to test the automotive ERP. Your team runs through your usual workflows using the system— submitting inspection logs, syncing EDI docs, logging downtime, whatever matters most to your operation. We collect feedback, fix what’s off, and make sure the system feels right before launch.

Once UAT is done, we prep your live environment. That includes final infrastructure configuration, database setup, and integration checks. If you’re migrating from legacy systems, we handle cleanup and import to ensure traceability stays intact. We can deploy module by module or site by site — whatever keeps your operation running smoothly. You see what’s getting built, test what matters, and steer the direction as we go.

Now, let’s talk modules — the ones that make your ERP software for automotive industry actually work for how your production runs day to day.

You don’t need every feature under the sun — just the ones that keep your operation moving without friction. Here are the modules we’ve built for our clients — features that fit the real needs of automotive ERP and keep complex operations moving.

Timing matters — and this module keeps your parts, materials, and production lines in sync.

It supports lean delivery models where components arrive in the right order, at the right time, with no excess stock sitting around. Real-time tracking via barcode or RFID keeps warehouses and production lines aligned. And with EDI in place, shipments and deliveries update automatically — no manual chasing, even with a multi-tier supplier network.

For UDK, a building materials manufacturer, we built real-time inventory sync that only showed stock available for immediate delivery — reducing delays and fulfillment errors. The same logic helps automotive teams avoid downtime and keep lines running.

In another project, route planning software, we used Azure Maps to optimize delivery routes using traffic, road constraints, and delivery windows. That same logic supports smart routing for incoming parts across regions or plants — critical for keeping just-in-time production on track.

This module handles everything from purchase orders to supplier scorecards — so you can focus on keeping production moving, not chasing paperwork.

It automates procurement workflows, contract approvals, and order tracking. EDI integration ensures real-time transactions with Tier 1–3 suppliers, cutting lead times and reducing errors. You also get built-in performance tracking — so quality issues, delays, and pricing fluctuations are easy to spot and act on.

For Strapping, we built a system that tracked supplier payments and flagged pricing discrepancies across orders. In automotive, the same approach helps manage complex supplier networks and catch cost issues before they grow.

This ERP for automotive manufacturing module gives you full control over what’s being built, when, and with what resources — even in fast-moving, multi-line environments.

It supports multi-level BOMs, MRP, and real-time production tracking. Automated scheduling and tools for smart resource allocation keep your lines running without constant manual fixes. With MES and IoT integration, you get visibility into equipment performance — plus predictive maintenance to prevent downtime before it hits.

When working on a factory surveillance platform, we integrated IoT sensors to monitor machine status, track energy usage, and detect anomalies in real time. That same setup in an automotive ERP enables predictive maintenance, live production tracking, and early warnings when equipment starts slipping — so you're not reacting to breakdowns, you're staying ahead of them.

Automotive standards leave no room for guesswork — so your ERP needs to help enforce quality at every stage, not just log issues after the fact.

We can design automotive manufacturing ERP systems that support compliance with IATF 16949, ISO 26262, and PPAP requirements. Features like lot and serial tracking, automated inspection logs, defect tracking, non-conformance reporting, corrective action management, and unified storage for audit-ready quality records help your teams spot and fix problems early — not after they hit the customer.

VIN-based traceability and structured recall tools make audits faster, warranty claims easier, and regulatory reporting less of a fire drill.

For Strapping, we built logic to handle rare edge cases like product returns and automatic inventory adjustments. The same approach applies here — whether it's EOL testing or recall prep, the system helps you stay precise, traceable, and audit-ready.

This module helps you track every cost, optimize spend, and spot issues that can affect profitability early — down to the part or production run.

It covers core workflows like cost accounting, budgeting, invoicing, and supplier payments, with built-in support for multi-currency operations and tax compliance across regions. If needed, it can also factor in environmental impact, such as CO₂ emissions tied to production or delivery.

For Vialoop, we integrated their ERP with NetSuite and a tax calculation service to automate financial reporting and ensure clean, compliant invoicing. In automotive, that means less time reconciling numbers and more clarity into cost per model, part, or supplier — wherever you operate.

For OEMs and distributors, the job doesn’t end at the factory gate. This module connects ERP for automobile dealers to the full post-sale lifecycle.

It supports dealer networks, fleet sales, and aftermarket operations with tools for warranty processing, service history tracking, and spare parts logistics. Integrations with CRM platforms and maintenance schedulers help streamline customer support, speed up service, and keep every system in sync.

Whether you’re managing vehicles in the field or coordinating regional parts centers, the ERP keeps sales, service, and supply aligned without extra overhead.

You can’t improve what you can’t see — this module gives you the clarity to act fast and plan smarter.

It brings together real-time dashboards, automated reports, and predictive analytics to track the metrics that matter most: production efficiency, supplier performance, cost trends, and more. From daily output to long-range forecasting, it keeps teams aligned and informed — without relying on spreadsheets or siloed tools.

In a telecom BPO project, we built a reporting engine that pulled data from multiple sources and revealed a €80K account discrepancy that had gone unnoticed for months. The same approach applies in automotive — clean, cross-system data helps you catch issues early and make decisions based on facts.

Your ERP doesn’t have to do everything — but it does need to connect everything.

We design ERP systems to work alongside the tools you already use, syncing data across your enterprise stack without adding complexity or duplication. That means smoother operations, fewer silos, and better decisions at every level. Common integrations include:

CRM platforms. Connect vehicle and spare parts sales, warranty claims, and customer data to get a complete view of post-sale relationships.

HR & workforce systems. Automate payroll, track labor compliance, and sync shift planning across plants and production teams.

Logistics management systems. Sync shipment tracking, delivery schedules, and inventory updates, so your supply chain stays visible and your team knows where every order stands.

These integrations cut down on manual work, improve data accuracy, and let you scale without rebuilding everything from scratch.

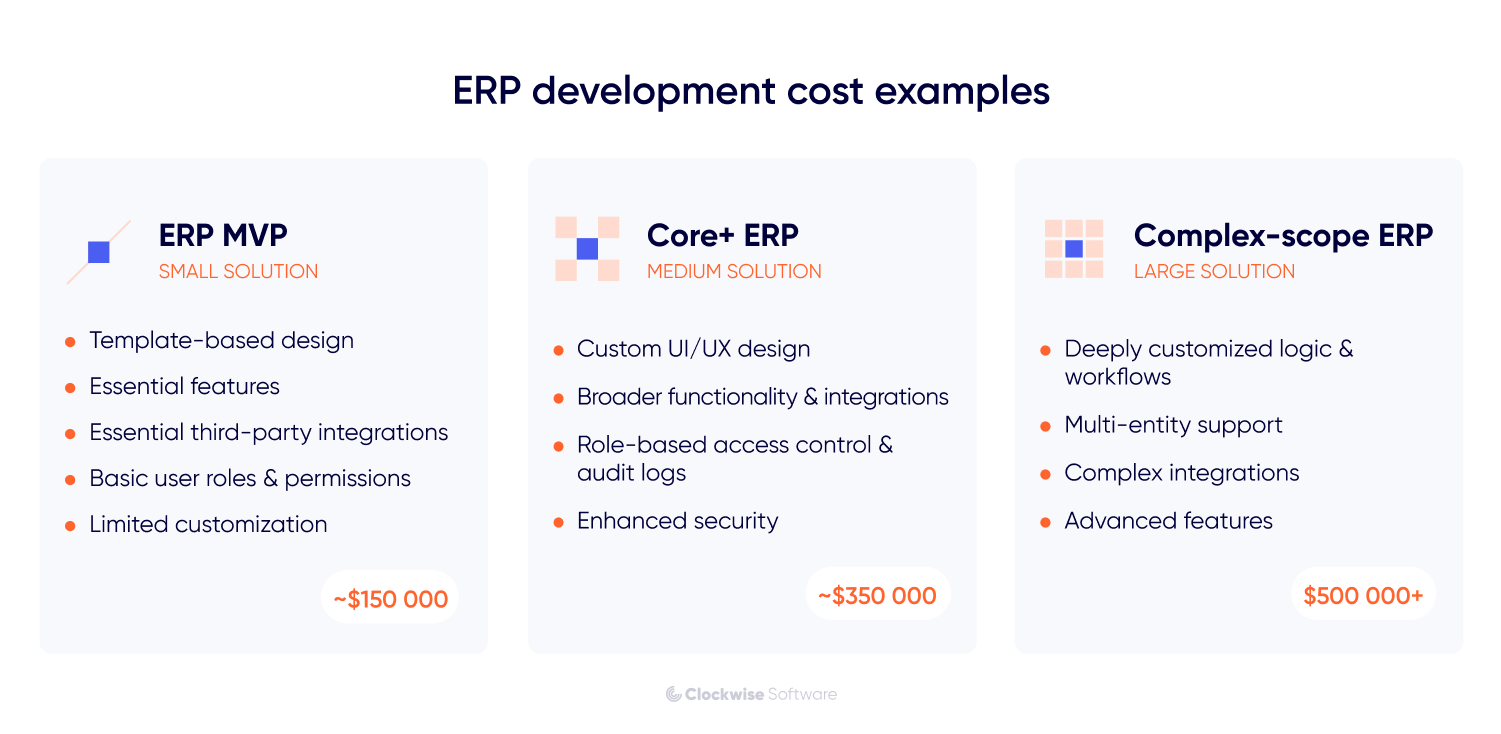

Now let’s get into the numbers: how we scope, plan, and price automotive ERP projects.

There’s no single price tag for automotive ERP software — the cost of custom software development depends on your goals, how many modules you need, and how complex your operations are.

If you're launching with an MVP focused on core functionality like production planning, inventory, and supplier management, the timeline is typically around 6 months, with costs ranging between $150,000 and $200,000.

For a full-scale automotive ERP system with deeper functionality — real-time analytics, traceability, compliance tracking, and aftermarket modules — expect a 9–12+ month build. Budgets for these projects usually start around $350,000 and increase based on the number of custom features and integrations.

You’ll get a full breakdown of cost, scope, and team structure up front — so you know exactly what you’re investing in.

To make things clearer, we’ve outlined three types of ERP builds — from a streamlined MVP to a mid-range setup and a full-featured system — so you can see which scope aligns with your goals.

If your goal is to move fast and stay focused, starting with an MVP helps validate the core system before scaling further.

Launching your automotive ERP is just the beginning. We stay involved after release — helping your team get up to speed, checking the data, fixing what’s off, and rolling out new features as your needs evolve.

We can start with a small support team or ramp up — depending on how fast you plan to grow. Whether it’s maintenance, new features, or integrations, we’ll adapt the setup to your needs. Here’s what a support setup might look like.

| Team composition | Monthly budget |

|

$12,000 |

|

$48,000 |

| * On-demand involvement | |

You choose the pace. We’ll shape the support model around your growth plans.

Already running an ERP but it's slowing your team down or missing the features you actually need? We’ll help bring it back in sync with how your business actually works.

Whether it’s poor UX, limited traceability, or gaps in integration, we can help bring your system up to speed with software development consultancy.

We start with a discovery phase focused on identifying what’s worth keeping, what needs fixing, and what’s getting in the way. Then we plan the upgrade — whether it’s reworking outdated modules, improving UX, or adding functionality that finally closes those gaps.

Some of the most common automotive ERP software upgrades we handle include:

Improving supply chain visibility. Add real-time tracking, supplier performance metrics, and EDI automation to prevent delays and improve forecasting.

Integrating modern tools. Connect your ERP with IoT sensors, MES, or AI-driven analytics for predictive maintenance, smarter scheduling, and better line visibility.

Streamlining compliance workflows. Automate traceability, audit trails, and reporting aligned with IATF 16949, ISO 26262, and other industry standards.

Upgrading the interface. Replace clunky layouts with clean, responsive views — so your team can get what they need quickly, even on the shop floor.

Connecting the rest of your stack. Integrate with CRM platforms, HR tools, and logistics systems to eliminate silos and make sure every part of your business has the info it needs.

You don’t always need a full rebuild. Sometimes a few smart upgrades are enough to get your automotive ERP back in sync with how your company actually works — and where it's headed next.

Whether you’re starting from scratch or upgrading a system that’s holding you back, the end goal is the same: fewer delays, cleaner data, and a system that keeps your operation moving — not slowing it down.

At Clockwise Software, we’ve spent the last decade building ERP systems for manufacturing-heavy industries. We know where generic platforms fall short — and how to build systems that actually solve problems on the ground.

If your current ERP is slowing you down, it might be time for a better fit. We’ll help you figure out what makes sense — and build around your real needs.